Although the application of lean construction has been significantly increasing on projects, tools that support its implementation through continue to remain limited. Production continues to be significantly managed through disparate systems driven by manual workflows.

Alignment of BIM with Lean practices

Previous case studies have proven that the use of BIM with lean practices during the construction phase improves the efficiency of planning. One of the major aspects of lean and BIM implementations is the support of the Last Planner® System (LPS) and tracking of production progress to ensure unhindered execution. While 4D planning has been used to support pre-construction planning and first-run studies, it has had limited success with tracking real-time production status and hence, in supporting LPS as well.

Case Overview

This case study provides insight into integrated lean-BIM implementation on a Data Centre project in Dublin, Ireland, constituting highly modular off-site production. The project effectively acted as a system comprising of hundreds of such off-site modules. Hence, the team had to factor in each micro-level-detail of logistics, production pace, resources, and other potential constraints.

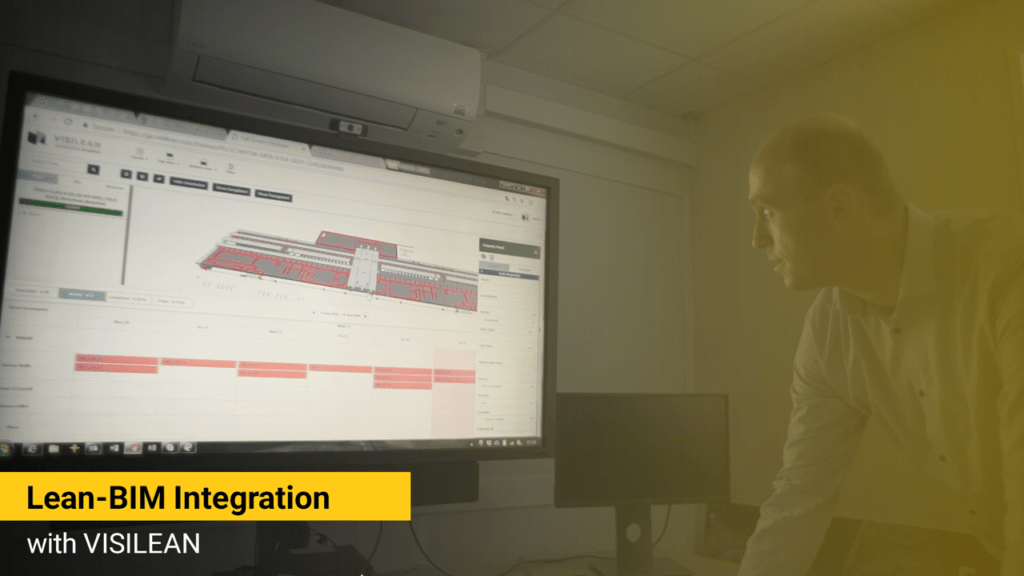

To help deal with this complexity, VisiLean was identified as a potential system that could replace the traditional sticky notes with a systematic tool that would help with not just micro-level planning, but also integrate it with the overall plan and BIM in order to improve predictability and tracking through powerful visual management.

Collaborative Planning

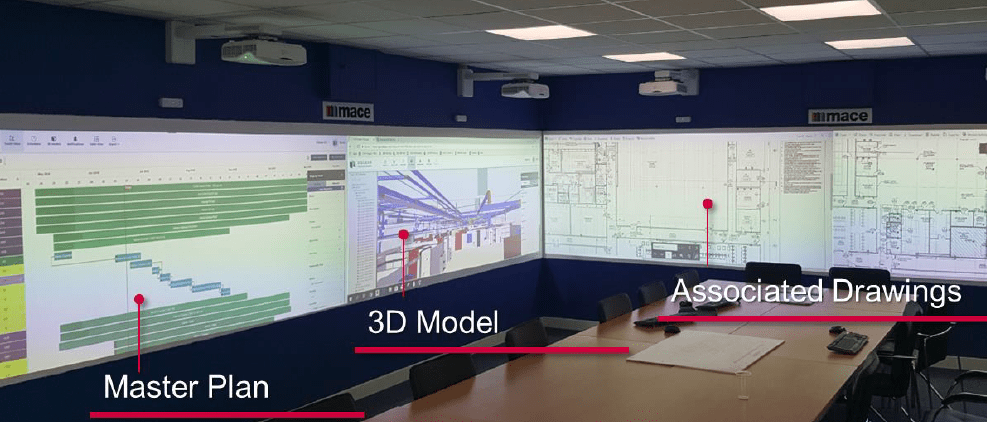

During the phase planning meetings, the entire supply chain would gather to pull work and commit to it. Look ahead meetings were held to collaborate over micro-level planning. VisiLean dynamically links production plans to the 3D BIM model, transforming BIM into a visual planning tool for the team.

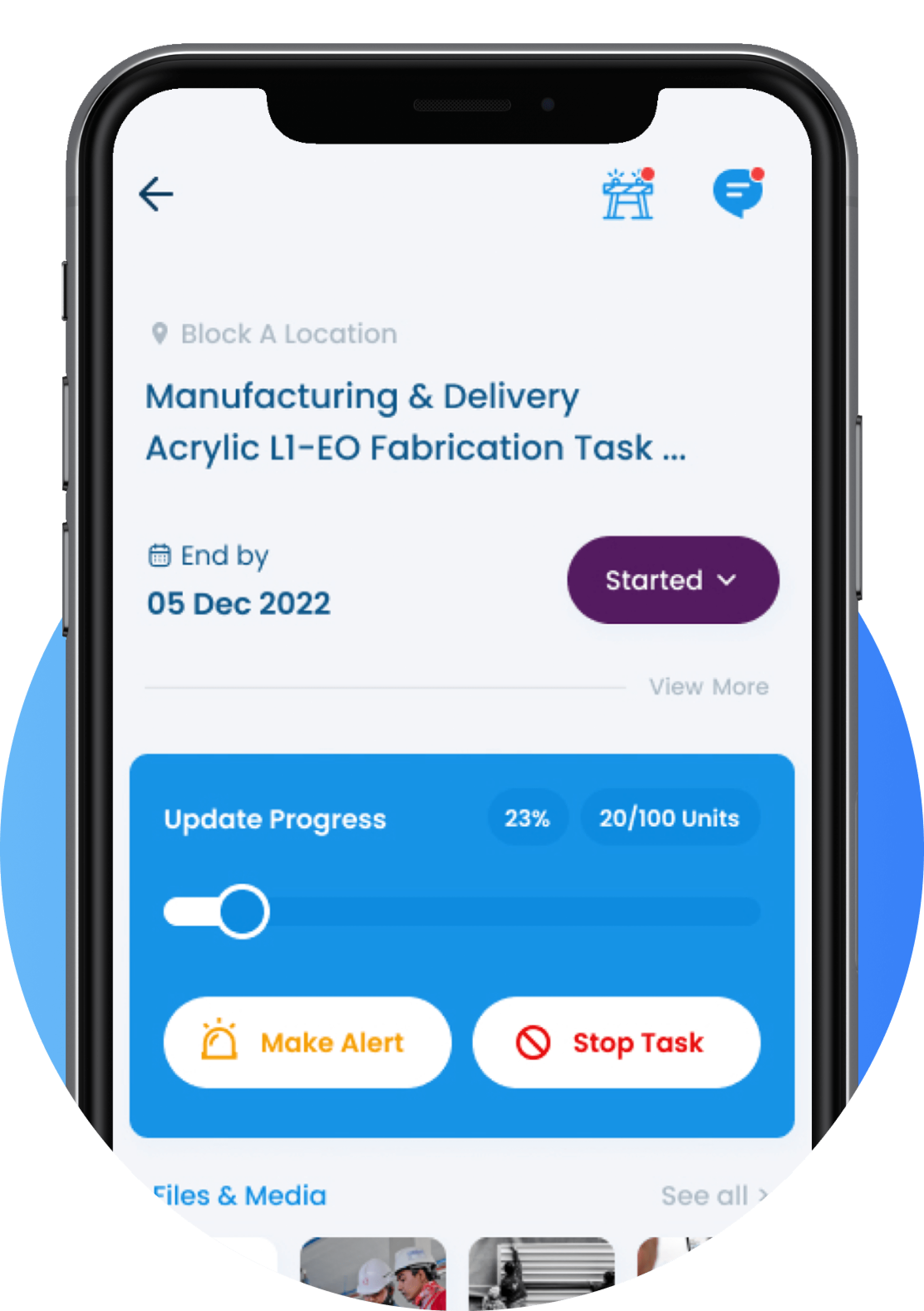

Managing the intricate sub-processes of Module production was a challenge that the team overcame by adding all the necessary details to the task ticket itself on VisiLean. Post the look-ahead meeting, each ticket of the schedule was able to provide details like owner, make-ready date, location, priority, important documents, quantities, plan constraints, and notes.

Establishing Production Control

Potential constraints and clashes pertaining to workspace, material, equipment, manpower, or design were identified as well as part of this process. Later, the prominent issues are discussed and sorted out in the weekly meetings, and the final commitments for upcoming production week were made.

The supervisors would update their work status directly from site using the VisiLean Mobile App. This also enabled smooth handovers as it prompted the subsequent task managers in real-time. Moreover, the task-related stoppage or breakdown data was helpful in reviewing the planning efficiency towards continuous improvement.

Integrated Lean-BIM for real-time Visualisation

The management of trade handovers was improved using 4D tools to track the activities in real-time. As a task flowed through its defined workflow, the team could follow its changing status visually and take proactive action whenever necessary. The collaborative planning system allowed greater communication between trades and identified opportunities to improve the workflow in each area.

Success Figures

60% reduction in defects,

43% improvement in program efficiency,

45% reduction in labour spend.

Ultimately the solution has enabled a safer, time saving and quality driven project delivery, whilst delivering a better and more efficient working environment.

Key Success Factors

Sustainability of the integrated lean-BIM effort, in this case, was achieved through the adoption of the production management system deployed (VisiLean), coupled with a dedicated team and a lean collaborative culture, driven by the Project Director. A regimented process was developed in collaboration with the supply chain that ensured strict discipline in the planning, scheduling, and control processes. Supported by VisiLean as the digital solution enabling this, the team could ensure that on-field process clashes were avoided, and learning was improved.