If you check the NBS BIM Report, 2020, you will come across a very interesting statistic – “BIM awareness and ‘use’ 2011 vs 2020”. From just 13% of survey respondents using BIM in 2011, we have now reached a staggering figure of 73% using BIM as of 2020.

This a very impressive growth in the use and deployment of BIM over the past decade. You, as part of the construction industry, might very much be a part of these survey respondents who are now using BIM.

In case you’ve been wondering; Is BIM the magic solution for the industry?

However, the question is this, have you managed to deploy BIM successfully for execution? If not, you won’t be the only one struggling with implementing BIM for the construction phase on-site.

Isolated Deployment of BIM

It is no secret that we are still plagued with isolated BIM development in the industry, where designers continue to work in silos, and coordination remains one of the biggest challenges for efficient design development. However, it is worth noting that there is also phase-based isolation, where design, pre-construction, execution, and facility management, all act as silos with different teams and completely different levels of BIM deployment.

Effectively, while most of the industry has deployed BIM for design development and clash detection, there is still a roadblock towards extending BIM uses to pre-construction and execution effectively. Even more limited is the consideration of operations and maintenance of the facility when implementing BIM for a project.

While BIM has evident benefits in design development and generating clash-free models, the benefits attained from extending BIM implementation over to project planning and execution is still a grey area.

BIM/Digitalisation is not an automatic solution for efficient project delivery – it is time to go beyond BIM!

Main Challenges to BIM for Project Execution

- BIM uses for construction planning and execution are rarely defined in the BIM Execution Plan

- BIM Models are rarely developed by designers with construction workflows in consideration

- It is difficult to account for detailed execution constraints during early stages of BIM model development

- Project execution teams are not skilled enough to work with “Design” BIM models to make them construction-ready

- Modeling challenges lead to inaccurate information – there is a significant level of articulation required to make BIM models appropriate for use in execution workflows

- Models rarely account for any form of constructability which limits their linking to production plans for accurate visualisation

- Models are still technically difficult to manage – the hardware requirements and powerful network connection are still very-real challenges at the ground-level

- Models are overloaded – In most cases there is too much information to work with and there is rarely a way to curate the information for each trade on-site.

The Real Challenge

You’re probably aware of most of the challenges listed above and have probably faced them during various stages of project delivery. However, the real challenge that is rarely highlighted is the simple fact that your project teams differ across project stages.

When teams differ across project stages, the same BIM models do not address the requirements equally. Each team has a different use of the BIM models, and this is a factor that the project team needs to consider during the inception of the project when defining the BIM deployment protocol.

It is difficult for teams to consider what another team down the line will require, especially when their deployment of BIM is varied considerably. For designers to consider detailed trade workflows requires intensive collaboration between project teams at a common level of understanding across the various stages of the project.

BIM is not ready for Execution

BIM is never ready for project execution and it won’t be till we take a conscious decision to deploy it in a manner that makes it construction-ready. It is worth noting that the process of BIM model development is effectively injecting facility information into a digital space to ensure the parties using the models can utilise this data for making this digital representation a reality on ground.

There is an intervention required in the design development stage that must account for construction workflows through collaborative means to ensure BIM models include the information required on-site. This process starts when drafting the BIM execution plan where you start to map the BIM uses for the project.

The Key is to Understand your BIM-Uses

Each BIM use is specific and requires a dedicated workflow for successful achievement and efficient delivery. For example, if 4D BIM is a BIM-use, one must ensure that the models are designed accurately according to the level of schedule and the 4D simulations be capable of development at each stage of the model LODs; i.e. a simulation developed at LOD300 will require a high level schedule for linking and will have a specific purpose of a high-level review of the construction sequencing.

As you start to deploy 4D BIM for detailed project planning, the LOD400 model will have to be accurately developed to link to the detailed project schedule with micro-level activities. Similarly, a 4D simulation required to understand site logistics workflows will require the site logistics elements to be accurately added to the models at the right stage of pre-construction for efficient planning of site mobilisation.

As 4D BIM enters the execution phase, the simulation will need to highlight production management areas, as well as focus on enabling production control practices. This requires not just accurate model deployment at the ground level, but also managing the models to focus on information required for significantly shorter time frames with real-time accurate data from site.

Read more about the deployment of BIM for live project monitoring using VisiLean on an infrastructure bridge project!

Way forward

At VisiLean, we are continuously working with teams on projects globally who are driving ‘lean’ tools and processes efficiently. We are also involved with various projects who are deploying BIM from design to execution, where we come across numerous challenges towards appropriating BIM for project execution and monitoring.

Read more about the deployment of VisiLean by Mace on this hyper-data center project for lean-BIM integrated production planning and control that helped them achieve 43% improvement in program efficiency!

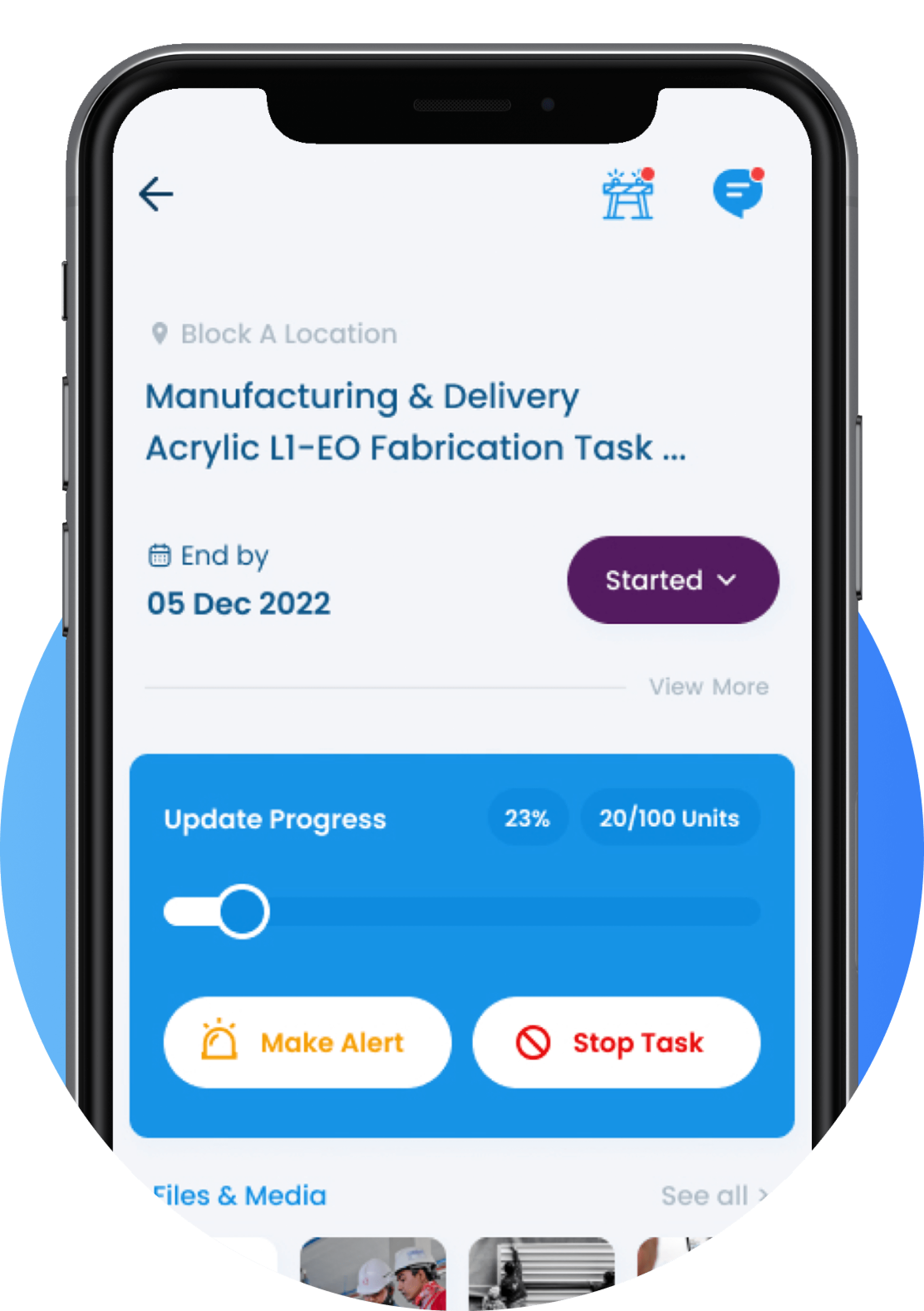

With the most powerful and unique Lean-BIM integrated production management engine, VisiLean enables you to successfully deploy BIM for production planning, monitoring, and control. With dedicated support and excellent system interoperability, we respect your teams’ familiarisation with existing platforms and workflows, promising smooth onboarding and transition across the organisation, one step at a time.

If you’d like to experience a true-lean service for yourself, head to the link here to start a fully-featured free trial – https://visilean.com/free-trial/

Want to know more about us? Head to https://youtu.be/vALoybf0zpM, or visit our website, https://visilean.com to learn about all our features!