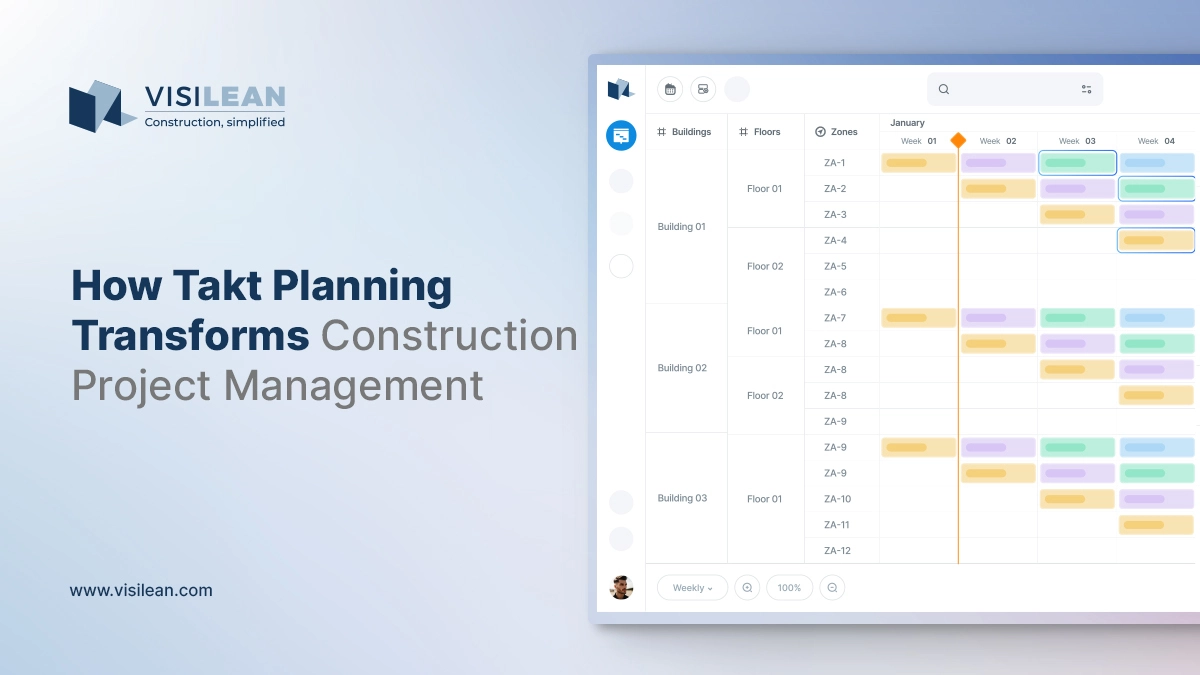

Introduction to Real-time 4D BIM Visualisation

The adoption of Building Information Modelling (BIM) in the construction industry has been documented for its successes. It enables lean outcomes. It enables efficiency across projects. The need to integrate BIM with production planning and monitoring systems like the Last Planner® System has been realised. This is to improve the exchange of information. Integrating BIM models with production management systems can standardise production schedules.

This uses relevant building and site information. With a 4D BIM model as a specific BIM use, the intent is to allow teams to visualise the product. This is before production begins. This approach enables efficient execution. It enables less rework. This, in turn, generates time savings. It creates cost savings for the project.

We are all familiar with the benefits of 4D BIM simulation videos. These are developed in tools like Navisworks®, which are great for viewing. They are developed by linking elements to the Master Schedule. These are a high-level programme. They typically drive the push approach of defining the schedule.

With projects driving Lean Production Management through the Last Planner® System for collaborative planning, such simulations have little bearing. They have no bearing on their pull-planning. These 4D videos do not contain real-time information. They do not relate to the production plans. Unless the 3D BIM models contain the correct parametric information relevant to the execution schedule, the true benefits are hard to harness. This requires the required level of detail and information to be in place. The benefits of integrating the construction schedule with BIM are hard to harness to their full potential.

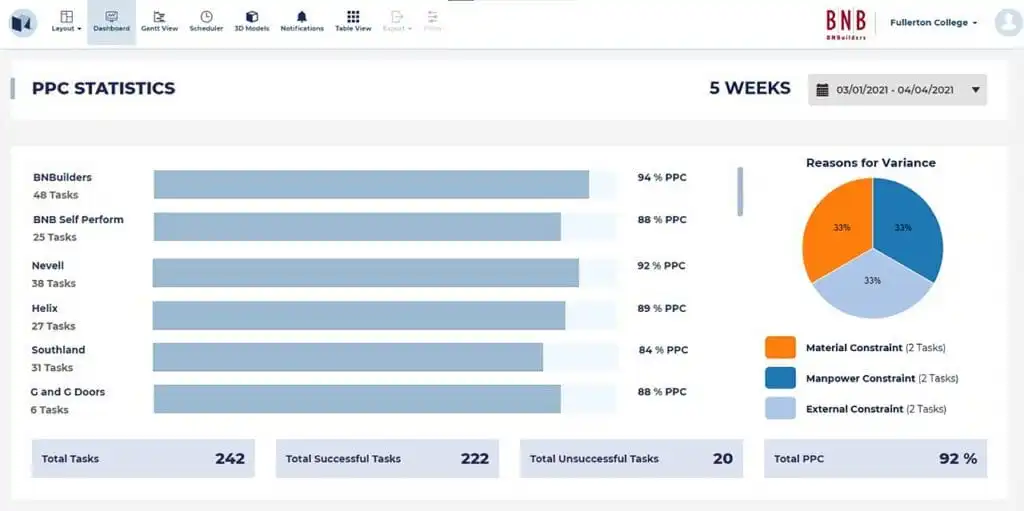

If you would like to get a glimpse of how VisiLean enabled BNBuilders to achieve a PPC of 90% through March 2021 on the project, watch our detailed video – https://youtu.be/vdlv3myXaL0

Challenges in Traditional 4D BIM Adoption

BIM Models are developed from a design perspective. They are primarily limited to use in the Design phase itself. This implies that the models can aid in design information, construction sequence, and other aspects. BIM models are either obsolete in terms of the updated design or simply not usable enough in terms of information to support the execution phase.

The reasons are the lack of detail and appropriateness required for this phase. There are challenges of technical limitations. There is a lack of resources. There is over- or under-detailing of the models. There is a lack of clarity on the level of detail. There is no involvement of the production team during the modelling phase, and so on. Due to the inconsistency and lack of accurate detail in the BIM models, monitoring these aspects of production management poses a significant challenge. This affects the achievement of the planned project timeline.

Real-time 4D BIM Visualisation for production planning & control – A Case study

VisiLean has been working with BNBuilders throughout COVID-19 on a 76,000 sq. ft. Instructional Building in Fullerton, California. The team utilised Lean planning and project monitoring tools. VisiLean has enabled the team to integrate its construction schedule. It has enabled them to access information from the site in real-time.

The construction process adopted by the team begins with creating a master schedule on a project scheduling platform. This includes tools such as Primavera P6 or Microsoft Project. The collaborative planning sessions take place in a closed room. The suppliers and the superintendents work with the P6 plan to derive lookahead plans on a board. This manual approach to pull planning posed a significant setback. This happened with the onset of the COVID–19 pandemic during the project.

For progress monitoring, the team would spend hours updating schedules. This was done by taking updates from the site. This approach, especially in the face of the COVID-19 challenges, ultimately put the project team at a disadvantage. They were constantly trying to chase the schedule rather than being proactive in resolving issues. When working on a recovery plan to bring the project up to pace again, this approach seemed to be in vain.

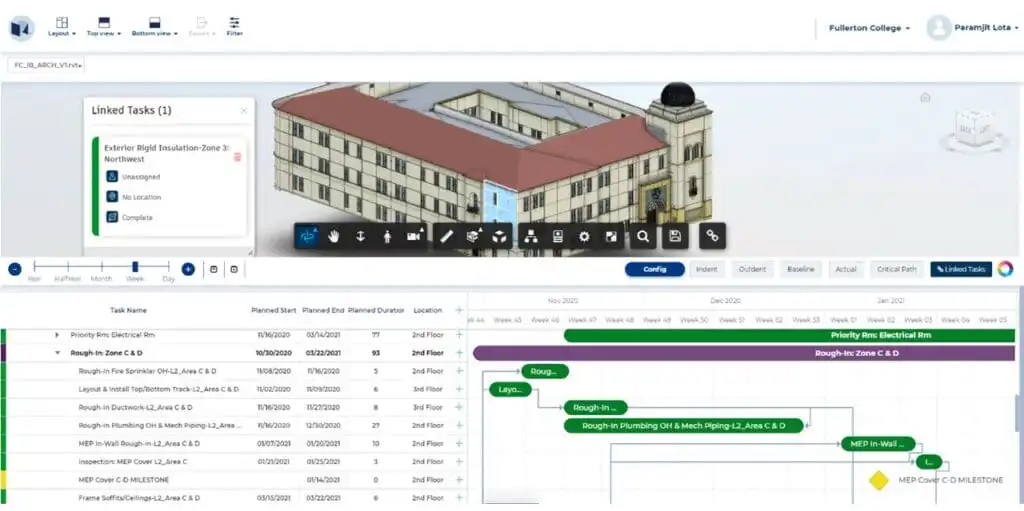

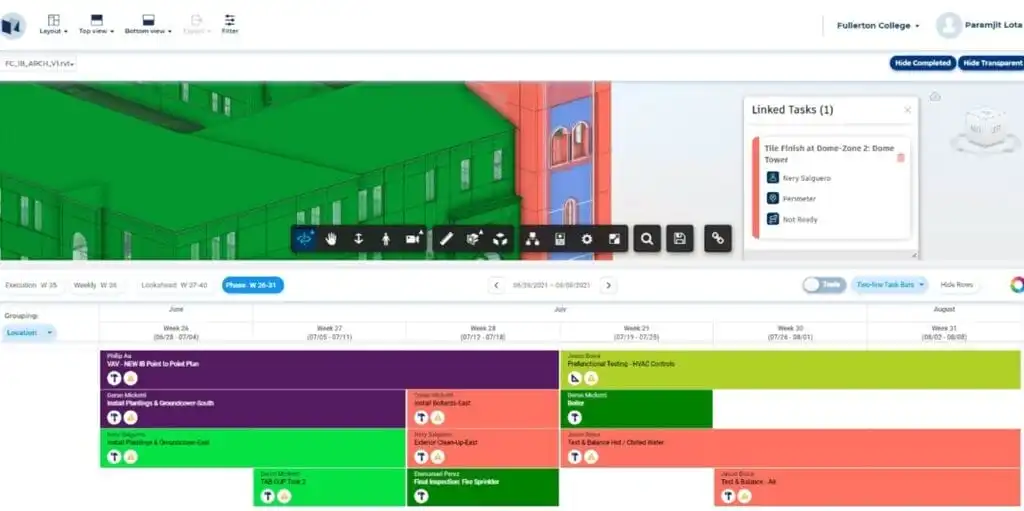

With VisiLean, the BNBuilders team adopted a revised planning approach. They could have all the subcontractors and the superintendents in the same environment. They could share their experiences and participate in the planning process. This process involved defining how each task impacts the other. This is critical to minimise waste in the process. This approach included using the existing BIM models. These were integrated with the pull plans to visualise the real-time progress.

Real-time 4D BIM for Construction Monitoring and Control

BIM integration was introduced to these collaborative planning sessions on the same platform. This allowed the teams to break work into detailed tasks. The linked element from the BIM model provided critical information regarding execution details. While reviewing the 6-week lookahead plan, teams could review the upcoming work zones. They could map any constraints that will hinder the actual execution of the job on-site. Critical aspects of safety, constructability, and site logistics emerged. These were documented as constraints to be addressed by the relevant owners.

This played a significant role in improving communication between the teams. Questions were raised about access, safety, and handovers amongst the trades. These were supplemented by the platform providing Task information alongside.

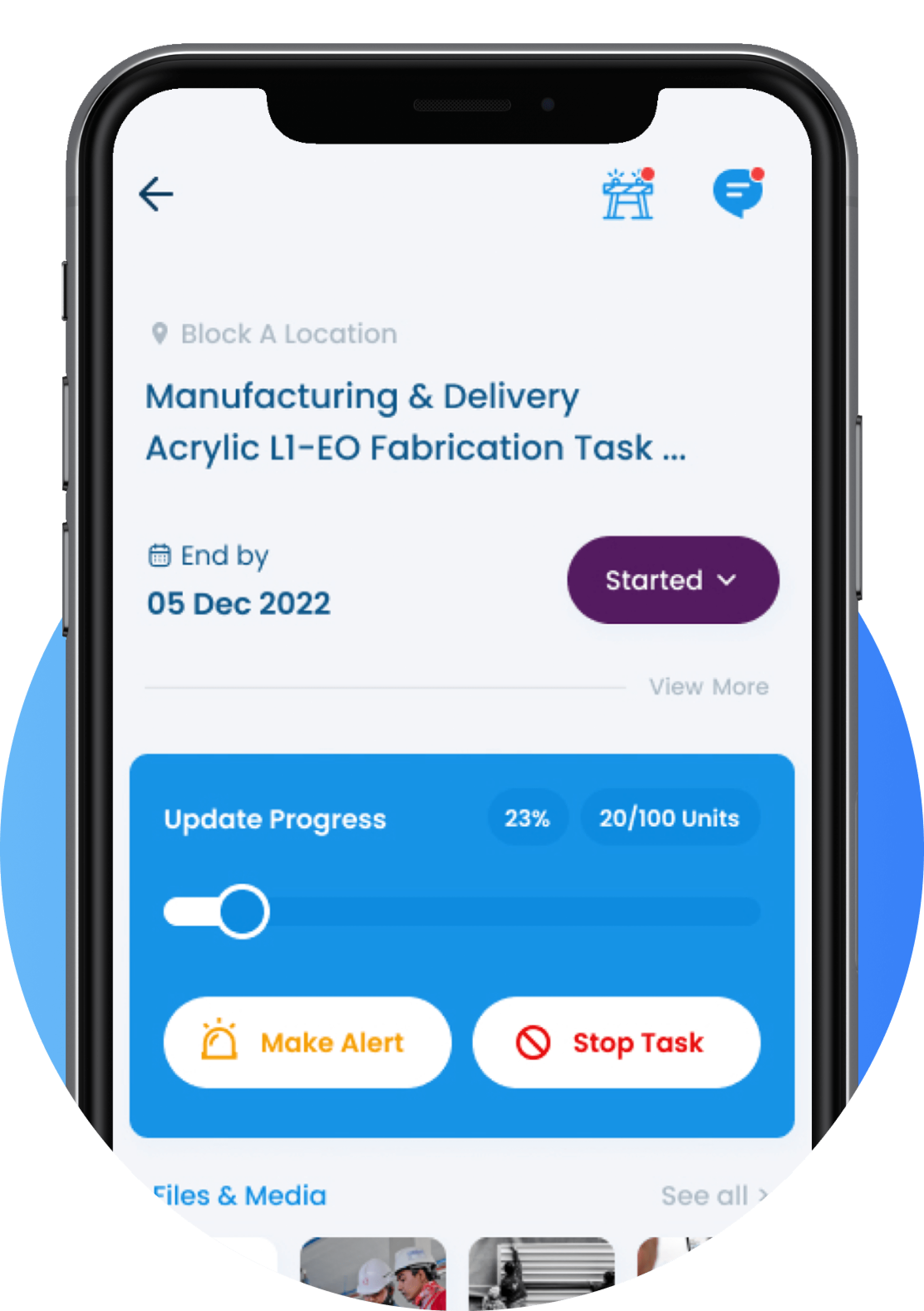

With the BIM model elements linked to these execution tasks, any update from the site was visualised directly on the model. This happened in a LIVE 4D representation of the construction progress on-site. This integration allowed not just for a visualisation of the work on site, but also for a status update. Clicking on the element would show the task owner, location, and all the other information supplied by the team on-site.

With live task status updates from the site through the mobile application, clear communication was established between the teams. The supervisors updated their work status directly from the job site. This came with the added convenience of sharing notes and images of the task being executed. Any update on the field was directly relayed to the team. This significantly saved critical time in communicating information through multiple channels, diluting it in most cases.

Benefits of Real-time 4D BIM in Lean Construction

With the adoption of lean construction processes as a client requirement, COVID-19 constraints, and a tool that could integrate everything, the project delivery approach underwent a radical evolution from reactive to proactive over the course of this implementation. Currently in the final commissioning phase, the project stands 6 weeks ahead of schedule, with an outstanding result of deploying the right tools and processes to ensure efficient project delivery. The benefits of 4D BIM realised during the project are listed below.

- Integrating the production plan with the top-level Primavera P6® plan. The system enabled the teams to break down the top-level plans into detailed, manageable tasks, update critical information on them, and integrate them back into the P6 program.

- Construction sequence integration with BIM gave them the power to visualise the project with its actual construction status. Teams could focus on the actual site status by simply looking at the BIM models, which had live task updates. Constraints were linked to these tasks, helping the team understand what needed to be resolved.

- The fact that project scheduling can be integrated with existing BIM models and provide teams on site with the ability to use the app on mobile devices, allowing for seamless updates to the same platform, would tie back all the way to the 3D BIM model.

- Access to real-time information empowered on-site teams to make critical decisions, which were essential to the project’s successful early completion. Not only did the GC deploy the Last Planner ® approach to collaborative planning through COVID, but they also managed to achieve a staggering PPC of 92% through the month of March 2021 (average of 5 weeks).

The Future of Real-time 4D BIM Visualisation

This integration is key to project scheduling and construction management in general. A typical 4D simulation recreated with an “updated” schedule from the site rarely provides an accurate picture of the status of work on-site. Multiple sources of information lead to genuine human error. This affects the credibility of the data and the trust and dependency between the various trades.

An integrated approach combining the schedule with a model, which is rarely used on-site, gives projects the edge needed to drive efficiency in production. This helps them achieve their targets, even in the face of COVID-19. As the case highlights, the revised Lean-BIM integrated approach played a crucial role in enabling this. It brought the project not only up to pace but to early completion.

At VisiLean, we continuously work with teams on global projects that utilise ‘lean’ tools and processes efficiently. We are also involved with various projects that deploy BIM from design to execution. Here, we come across numerous challenges in adopting BIM for project execution and monitoring.

VisiLean offers you the most powerful and unique Lean-BIM integrated production management engine. It enables you to successfully deploy BIM for production planning, monitoring, and control. Plus, we promise a smooth onboarding and transition across the organisation, one step at a time.

Download the full case study here.

If you’d like to experience a true-lean service for yourself, click here to start a fully featured trial.

Frequently Asked Questions (FAQs)

- What is 4D BIM, and how does it differ from traditional BIM?

4D BIM integrates time-related scheduling information into 3D BIM models. It allows teams to visualise the construction sequence over time. 4D BIM enables real-time planning, execution, and progress monitoring.

- How does real-time 4D BIM help in construction project management?

Real-time 4D BIM enables stakeholders to visualise live task status updates. It also helps identify constraints and make data-driven decisions. This bridges the gap between planning and execution. Moreover, it enhances communication between field and office teams to minimise rework.

- What were the key challenges with traditional 4D BIM implementation?

BNBuilders reported a 6-week early completion and achieved an average PPC (Percent Plan Complete) of 92% in March 2021. The real-time integration of scheduling, BIM, and field updates played a critical role in this outcome.

- How did VisiLean support BNBuilders during the COVID-19 pandemic?

VisiLean enabled BNBuilders to shift from manual planning and delayed reporting to a collaborative approach. The platform integrated lookahead plans with BIM models and allowed mobile updates from site teams, resulting in proactive issue resolution and improved productivity.

- Can 4D BIM be used for pull planning in the Last Planner® System?

Yes, when integrated with tools like VisiLean, 4D BIM can support pull planning by linking tasks to BIM elements and making execution details visible. This enhances coordination and ensures the plan reflects real-world site conditions.

- Is VisiLean compatible with platforms like Primavera P6 and Microsoft Project?

Yes, VisiLean supports seamless integration with top-level schedules from tools like Primavera P6® and Microsoft Project®, allowing detailed task breakdowns and live updates while retaining compatibility with existing project workflows.