The significant impact of this global pandemic on the industry is the limitations now offered by our existing practices. Our workflows are primarily manual in nature, with a lot of physical involvement of teams. Though in principle, actual construction work needs to be executed by hand on-site, a whole journey leading up to and from that moment can surely cut down on some of these interactions.

The Digital-buzz

There have been a lot of talks recently about digitisation, digitalisation, modularisation, technological innovation, and so on. Buzzwords like Construction 4.0 are circulating across the industry. While this might seem exciting to some, it can also prove to be very overwhelming for others.

Industry Relevance

It is critical to understand where these trends come from and what they promise to offer. Digitalisation comes in numerous forms when we talk of construction project delivery. However, we need to skip heavily manual processes in our workflows to simplify the flow of information and data amongst our teams. This form of digitalisation is now essential when most of us are anyway working remotely or trying to minimise physical interaction.

Manufacturing Construction

Further to this, if we can take some of our construction off-site, and start “manufacturing” in controlled environments, we can boost productivity considerably, while also ensuring the highest of safety standards for our teams deployed. This too is supported by digitalisation, wherein you can plan, monitor, and track the production remotely.

The Digital Revival of Construction

It is evident that as an industry, there is a clear requirement to digitalise our processes to minimise physical involvement and manual intervention to simplify work, have a precise flow in processes, and minimise wastage in terms of challenges offered by the present global situation.

Furthermore, with such practices running, one can better ensure the safety and well-being of teams deployed, thereby driving and maintaining a healthy culture of value generation and continuous improvement in the organisation. Along with physical safety, it is extremely important to ensure the cultural well-being and morale of our teams.

Digital Planning for Efficiency and Safety

For anyone familiar with sticky-note planning, the thought of the physical presence of all the teams in one room can now seem overwhelming. We need a common platform to visualise our project plans and discuss look-ahead planning, constraint mapping, and committing to our production plans.

Unless you have cameras at every corner of your site, it is scary to even imagine managing a team full of workers out there, ensuring the best of safe-distancing practices. What can be done, however, is to plan better and ensure that limits can be defined for each location and the workforce is accordingly assigned to tasks to avoid overcrowding.

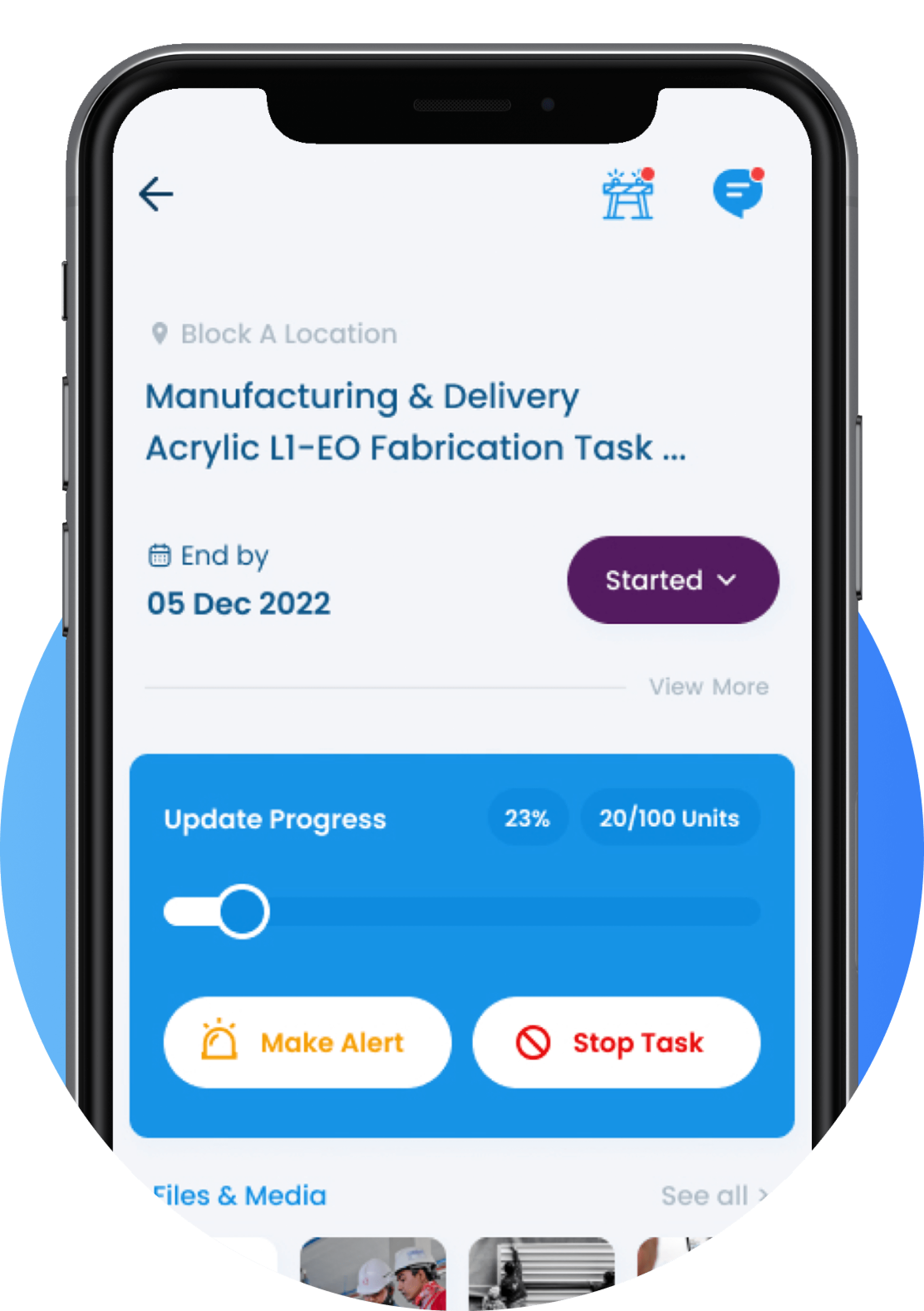

Digital Monitoring, Tracking and Reporting

With limited access to sites, and ensuring minimum physical interaction between teams, we need to digitalise the flow of updates from site to all the relevant stakeholders. All the information must be seamlessly available to teams on a common platform for collaborative review, thereby focusing on driving productivity forward rather than recording the information safely.

Just Digital?

Did the terms flow, waste, value, and continuous improvement, mentioned earlier, sound familiar? Well, digitalisation alone is not the solution here. In times where acclimatisation to the “new normal” itself is a big challenge, exploring new opportunities always takes a backseat, and changing behaviour and mindsets often becomes a bigger roadblock.

This is where Lean processes can help enable this transition based on the proper alignment of tools and practices deployed and your team’s cultural setting. A top-down approach to deploying solutions is hardly ever successful in penetration.

Where should you begin?

Although the scope of digitalisation is immense, with today’s systems and solutions offering endless possibilities to the extent that you could deploy 10 drones on your site tomorrow, it is crucial to understand what is appropriate for you. It is essential to begin somewhere and take the proper first steps, enabling wider acceptance amongst your teams.

With VisiLean, we address the heart of construction production management. With dedicated modules to digitalise your production planning, monitoring, and tracking and the correct set of tools to provide production control, VisiLean helps you transition seamlessly towards Lean digitalisation. With dedicated system interoperability, we ensure we respect your teams’ familiarity with existing platforms, promising smoother onboarding and acceptance across the organisation.

If you want to take the first steps towards digitalisation and save significant time and cost on your construction projects, sign up for a fully featured free demo at VisiLean.

Want to know more about us? Head to https://youtu.be/vALoybf0zpM or visit our website, https://visilean.com, to learn about all our features!