Anyone who has worked on a construction project knows about the constant “firefighting” the team has to put up with. Every day brings new challenges posed by managing constraints in construction that have seemingly emerged out of nowhere. However, the lean production principles and the method of “pull planning” teach us that if we address the “constraints” beforehand and commit to resolving them, we can certainly bring to the fore the “unforeseen” issues and address them before they result in a fire.

A constraint is typically a resource that is required to successfully start or complete a task. This can take the form of a physical resource, i.e. construction materials, equipment, such as cranes or concrete mixers, or a non-physical one, i.e. permit to proceed, design specification, etc.

Usually communicated by word-of-mouth, this vital information gets diluted or missed out by the team, and in the weeks to come, the potential constraint becomes a full-fledged problem halting work on-site.

This article outlines the importance of active constraint management which is essential for the make-ready process.

Lean Pull-Planning

Lean construction and the Last Planner method propose the use of pull-planning, with a keen focus on mapping potential constraints that may affect the successful start or completion of a construction task. After defining the flow of production in the phase plan, the look-ahead window allows you to collaborate with your team to visualise constraints.

Constraint Mapping

To ensure reliable commitments, constraints must be identified and assigned to responsible actors for active resolution. This process typically takes place during the look-ahead planning stage (i.e. 3-6 weeks before the tasks enter production). While reviewing the weekly plan, the team then ensures that the constraints have been removed before releasing the activity for production.

Make-ready Process

Typical Constraints attached to activities

Though there can be various types of constraints specific to a project, the typical prerequisites such as material, space, and manpower, are checked before the work is actually started on-site. This considerably minimises unexpected halts or issues during the execution of the work, ensuring production flow and smooth handovers.

General Site Constraints

Over and above constraints specific to Tasks, one can face potential problems on-site for a number of other reasons. Access routes could be blocked, safety arrangements could be inadequate, or specialised equipment or teams could be required. While some could be related to activities to be executed, others could be general issues affecting the flow of work on-site, or related to the supply chain.

Documenting Constraints

Therefore, it is essential to forecast potential constraints, document them, and assign responsible actors for action. The documentation should be based on a thorough assessment to accurately categorise and prioritise the potential issue. Following this, the actor should take necessary actions to mitigate the constraint in due time, and accordingly update the team upon any action taken.

Sounds like a lot?

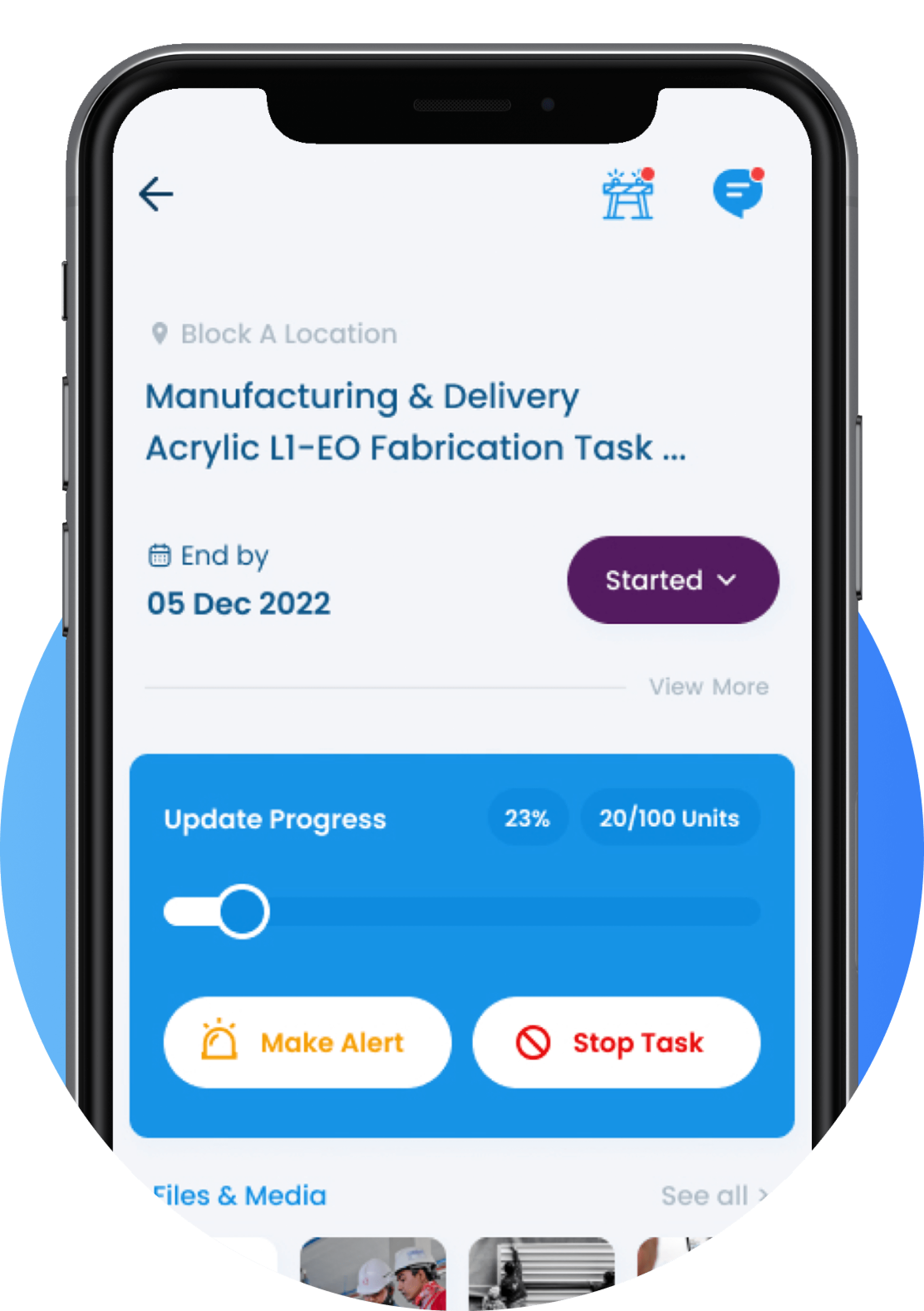

That’s exactly why VisiLean is here to simplify things for you! In addition to our predefined “pre-requisites” checklist, we have just added the ability to define custom constraints which can be generic or task-specific.

Constraint Management with VisiLean

With this latest feature, you can now thoroughly document your constraints by adding all the necessary information. From defining the priority and categorisation to assigning the responsible actor, you can also link the constraint to specific Tasks to have a complete record of the constraints.

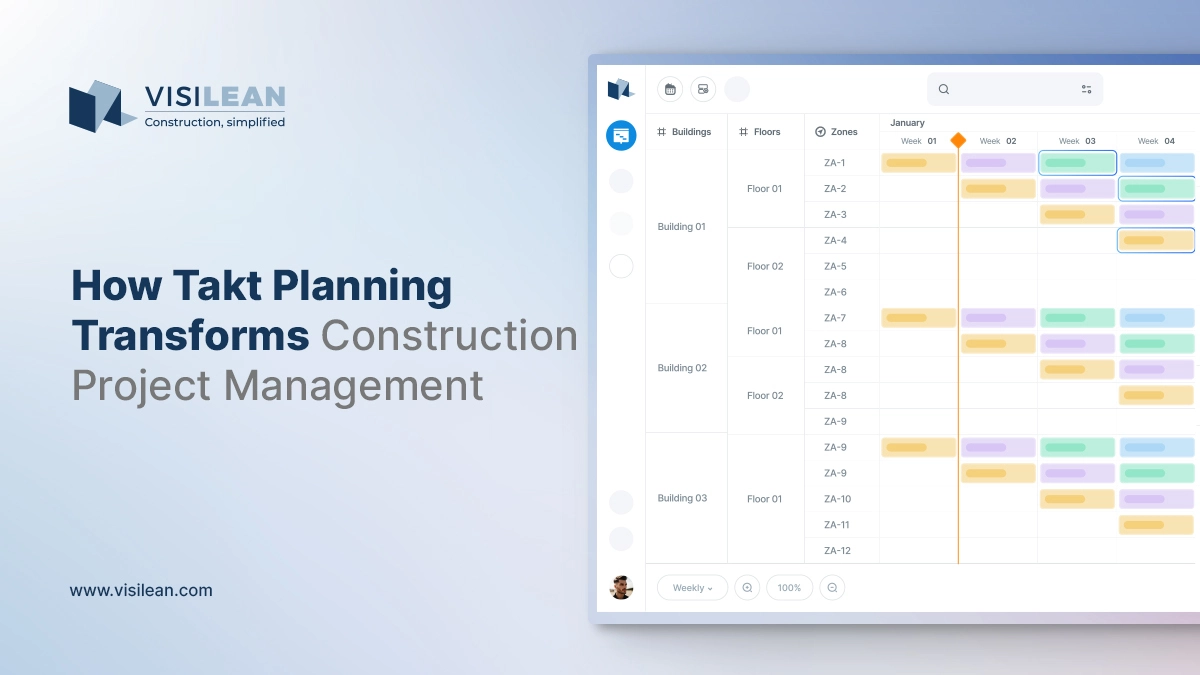

All this information is documented in a constraint log, with a dedicated widget on the Dashboard highlighting the status for a quick review. With pull-planning enabled by the Scheduler view on VisiLean, you can digitally collaborate with your team over your look-ahead plan, while simultaneously mapping potential constraints and documenting them in the constraint log for further action. The mobile apps then let your workers manage constraints when they are in the field.

Digitalisation with VisiLean

At VisiLean, we are constantly striving to enable the digitalisation of construction project delivery in a simple, lean manner. This newest addition of a digital constraint management system is another step towards enabling this transition for you.

Start your digital journey today by beginning a free demo with us.

VisiLean is a cloud-based Lean construction management software that enables real-time communication and collaboration between your project teams. Manage your constraints effectively with VisiLean. Check out the latest features and the proven benefits VisiLean provides at https://visilean.com

Want to know more about us? – https://youtu.be/vALoybf0zpM