What is the Last Planner® System?

Last Planner® System (LPS) is a collaborative planning and control system that shifts the focus from top-down scheduling to commitment-based planning. It ensures that tasks are realistically planned and completed as scheduled. It helps bring order to chaotic sites by improving collaboration and planning.

It involves:

- Phase Scheduling: Long-term planning (e.g., project milestones planning).

- Lookahead Planning: Mid-term (4/6/12 weeks) planning to identify and resolve constraints.

- Weekly Planning: Short-term commitments from teams.

- Daily Huddles: Quick updates to keep tasks on track.

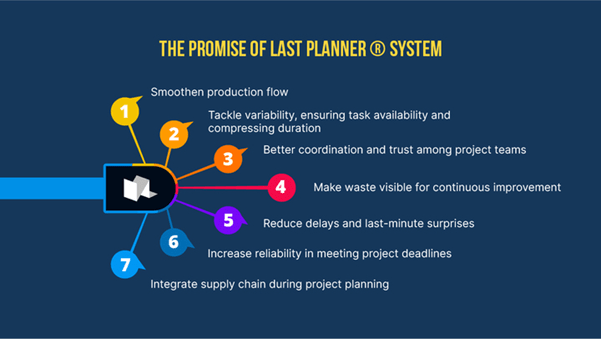

The Promise of the Last Planner® System

When done right, LPS helps to:

- Smoothen production flow

- Tackle variability, ensuring task availability and compressing duration

- Better coordination and trust among project teams

- Make waste visible for continuous improvement

- Reduce delays and last-minute surprises

- Increase reliability in meeting project deadlines

- Integrate supply chain during project planning

Despite its advantages, real-world implementation often faces several obstacles.

Challenges in the Implementation of LPS

The challenge areas limit the effectiveness of the Last Planner® System if not tackled properly. Most companies only scratch the surface of LPS. Some of the common challenges with its solution are listed below:

2. Inefficient Information Flow: Many teams still rely on spreadsheets and disconnected tools, making it challenging to track real-time progress. Data gaps prevent early identification of constraints, leading to delays and inefficiencies.

3. Limited Use of Continuous Improvement: One of the most significant benefits of LPS is its ability to learn from past issues. Many teams fail to conduct root cause analysis for missed tasks. Without data-driven insights, teams repeat the same mistakes.

4. Resistance to Change & Training Gaps: Many construction professionals lack formal training in LPS and show some resistance to adopting new processes, leading to inconsistent implementation.

Read more about (Why is Lean so Difficult?)

How VisiLean Provides a Holistic Solution?

These challenges might seem daunting, but the good news is that they are surmountable. While LPS is fundamentally a methodology and a mindset, modern technology can be a powerful enabler. This is where platforms like VisiLean step in to support and amplify your LPS implementation, ensuring you don’t just “scratch the surface.”

VisiLean provides a comprehensive digital environment that directly addresses the recurrent problems identified by research:

For Incomplete Adoption

VisiLean’s integrated platform seamlessly links all planning levels from master schedules to detailed lookahead plans and weekly work commitments. This ensures a consistent, end-to-end planning flow, fostering a complete LPS implementation rather than fragmented efforts.

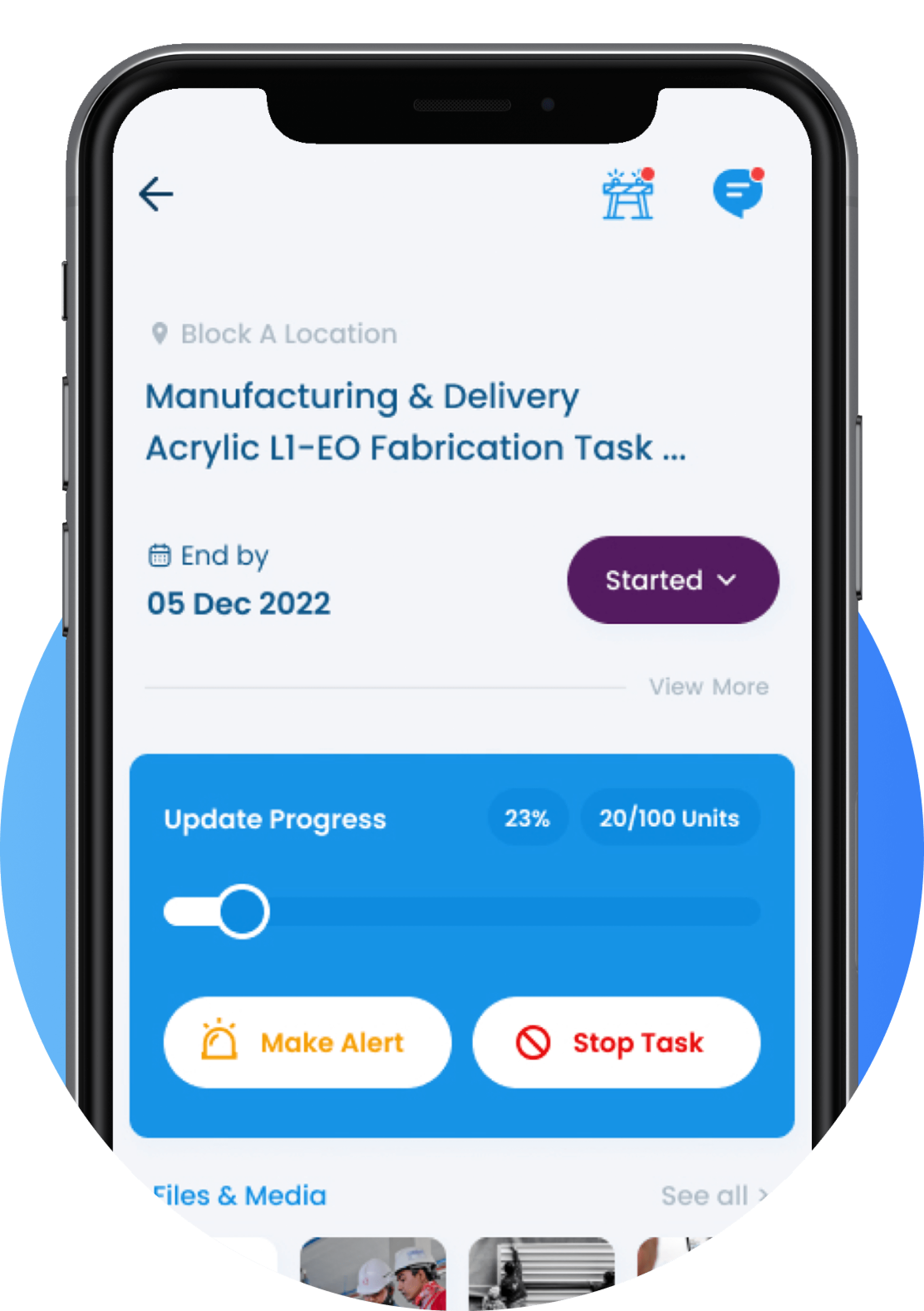

For Data Fragmentation & Poor Visibility

VisiLean acts as a unified cloud hub for all your project data. It centralises planning information, offers a dynamic, cloud-powered view of your project, always current, and provides real-time progress tracking via its mobile app (LiveSite). This eliminates data gaps and ensures everyone has access to accurate, up-to-the-minute information.

For Insufficient Learning from Experience

VisiLean’s robust analytics and customisable dashboards enable systematic tracking of key performance indicators like PPC, identifying delays, and analysing reasons for non-completion. This data-driven approach facilitates genuine root cause analysis and fuels continuous improvement cycles, transforming lessons learned into future successes.

For Cultural Resistance & Training Deficits

VisiLean’s intuitive, user-friendly interface and mobile accessibility significantly lower the barrier to adoption, even for those with less digital experience. By standardising workflows and providing visual cues, it guides teams through the LPS process. While training is always essential, the platform’s design supports a smoother cultural transition towards a digital-first planning mindset.

For Lack of Consistent Accountability

VisiLean fosters accountability by clearly assigning task ownership, enabling subcontractors and field teams to update their own tasks directly. The platform supports proactive flagging of constraints and discrepancies, facilitating timely discussion and resolution during collaborative planning meetings, ensuring commitments are maintained.

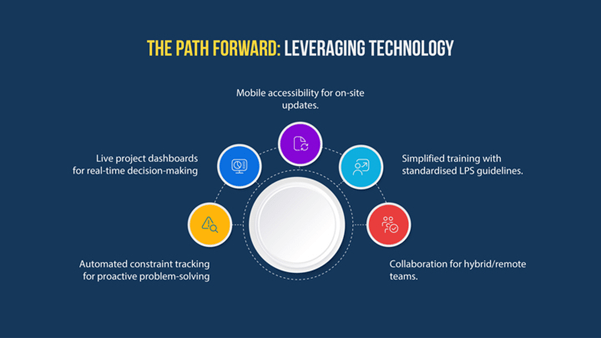

The Path Forward with Technology

The construction industry is evolving, and digital solutions are making LPS implementation easier and more effective. Platforms like VisiLean integrate LPS with real-time tracking, automating workflows, and BIM-based visualisations, ensuring teams stay on track with their plans. Here’s more:

- Automated constraint tracking for proactive problem-solving

- Live project dashboards for real-time decision-making

- Mobile accessibility for on-site updates.

- Simplified training with standardised LPS guidelines.

- Collaboration for hybrid/remote teams.

Conclusion

The Last Planner® System isn’t broken, it’s just underutilised. Its successful implementation requires overcoming challenges in collaboration, information flow, and training. By leveraging technology and fostering a continuous improvement mindset, construction teams can unlock higher efficiency, reduced delays, and more predictable project outcomes.

“LPS isn’t a magic bullet. It’s a mindset shift, one that pays off when everyone commits.”

📢 Ready to enhance your construction planning? Read the entire research paper here: https://www.researchgate.net/publication/280840529_Exploring_the_Recurrent_Problems_in_the_Last_Planner_Implementation_on_Construction_Projects