Despite years of research, innovation and adoption of construction technologies, the construction industry continues to face challenges like productivity, coordination and more. Numerous initiatives have focused on deploying Information and Communication Technology (ICT) to address the challenges, still the results have often fallen short of expectations.

As argued in the seminal research by Dr. Bhargav Dave, Lauri Koskela, Mike Kagioglou, and Sven Bertelsen, technology alone cannot resolve the fragmentation inherent in construction. ICT systems must be purposefully integrated with both the operational processes that govern project delivery and the human systems that execute them. Simply put, technology must not operate in isolation but must act as a unifying infrastructure that enables better collaboration, decision-making and control.

This article builds on their framework to explore how the integration of people, process, and ICT forms the foundation for more effective construction project delivery. Moving ICT becomes an enabler of transformation only when aligned with the way people work and how construction processes are designed to flow.

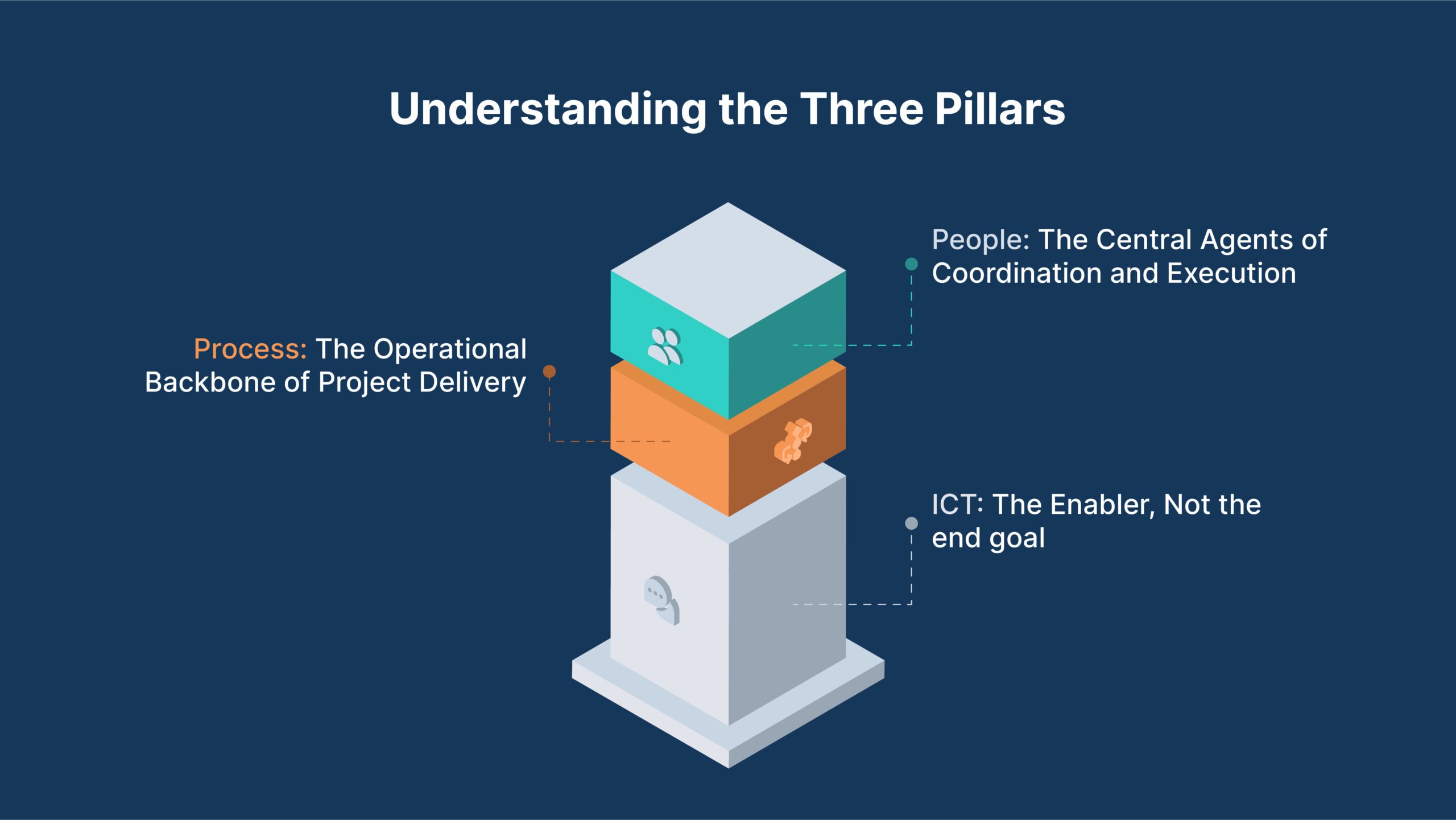

Understanding the Three Pillars

The successful delivery of construction projects hinges not merely on technological advancement, but on the synergistic alignment of three foundational elements: People, Process, and Information and Communication Technology (ICT).

Each of these pillars contributes distinct value to a project’s lifecycle, yet in isolation, their impact remains limited. True performance gains emerge only when these elements are integrated into a unified operational framework.

People: The Central Agents of Coordination and Execution

People are the active agents who interpret data, make decisions, and execute tasks. Despite increasing digitisation, construction remains a highly collaborative and human-intensive industry.

However, this collaboration is frequently undermined by role-based silos, fragmented communication, and reactive decision-making. The lack of shared situational awareness and coordination across stakeholders often leads to rework, misaligned expectations, and schedule slippage.

Empowering people with real-time visibility, shared planning environments, and clear accountability is essential not just for task execution but for building trust and sustaining continuous improvement.

Process: The Operational Backbone of Project Delivery

Construction processes are inherently complex, involving dynamic interdependencies, variable conditions, and constant adjustments. These characteristics render traditional command-and-control approaches inadequate.

Without structured workflows and continuous feedback loops, teams struggle to maintain flow, manage constraints, or respond effectively to emerging issues. Process inefficiencies, often latent, are a key contributor to low productivity and high project risk.

Lean Construction offers a robust foundation for process thinking. By emphasising workflow reliability, constraint removal, and collaborative planning, Lean transforms construction from a fragmented activity into a managed flow of value. But process thinking must be embedded into everyday practice, not treated as a one-time intervention.

ICT: The Enabler, Not the end goal

Information and Communication Technology (ICT) has become ubiquitous in modern construction, from Building Information Modelling (BIM) and scheduling software to mobile inspection tools and cloud-based dashboards. Yet, despite widespread adoption, project outcomes have remained stubbornly resistant to improvement.

This paradox arises because ICT is often deployed in a technology-first manner, without reconfiguring underlying processes or addressing the needs of the people expected to use these systems. The result is an array of disconnected tools that fail to support real-time decision-making or frontline collaboration.

For ICT to deliver meaningful impact, it must be:

- Intentionally aligned with process objectives,

- Seamlessly integrated into daily workflows, and

- Designed to enhance, rather than replace, human coordination.

Why Improving One Pillar without the others Yields Limited Results?

In construction, isolated advancements, whether in tools, workflows, or workforce capabilities, are often met with diminishing returns when not supported by a broader systemic alignment. The reason lies in a fundamental truth: the pillars of People, Process, and ICT are interdependent, and gains in one domain cannot be fully realised unless reinforced by progress in the others.

Technology Without Process Alignment Leads to Fragmentation

A common misstep is deploying advanced technologies, such as BIM platforms, scheduling software, and mobile apps, without restructuring workflows or rethinking team collaboration. While these tools may enhance data capture or reporting, they often become isolated layers of digital documentation with minimal bearing on site-level decision-making.

Without a process framework that governs how and when information is used, even the most sophisticated tools fail to drive proactive action. For example, task updates captured in digital systems offer little value unless they feed into a live planning mechanism that supports constraint identification, lookahead planning, and flow improvement.

Process Improvement Without Enabling Technology Limits Scalability

Conversely, process-focused efforts such as Lean Construction training, Last Planner workshops, or visual management boards can yield measurable improvements in reliability and coordination. However, in the absence of a scalable digital platform, such initiatives often struggle to sustain momentum beyond isolated teams or pilot projects.

Manual processes, while valuable for culture building, limit visibility, restrict real-time collaboration, and cannot keep pace with the demands of large, multi-site, or fast-track projects. Without ICT integration, process improvements become hard to track, audit, or institutionalise across the organisation.

Skilled People Without Systems Support Face Operational Friction

Construction teams are often staffed with capable professionals who possess deep domain expertise. Yet, when operating within fragmented systems, unclear workflows, siloed tools, and reactive planning environments, even the most skilled individuals face constant operational friction.

Without a structured process to guide execution and without digital tools that provide transparency and timely information, individuals spend more time navigating complexity than delivering value.

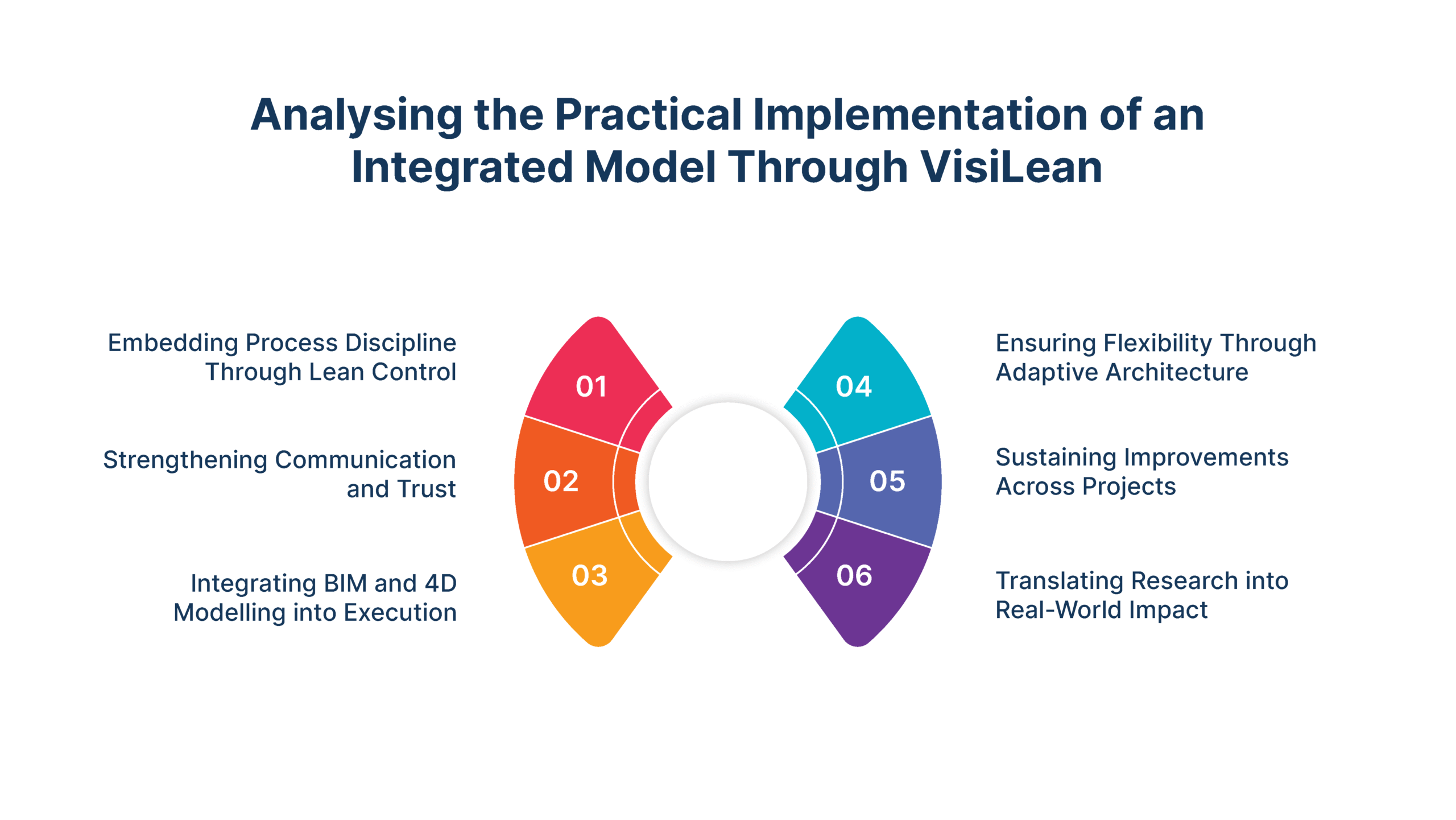

Analysing the Practical Implementation of an Integrated Model Through VisiLean

The integrated People–Process–ICT model described in the research demands that technology not be an isolated add-on, but a mechanism deeply embedded into the operational core of construction. VisiLean operationalises this principle by aligning process discipline, collaborative behaviours, and digital tools into a single production control environment.

Embedding Process Discipline Through Lean Control

The research emphasises that ICT is most effective when it reinforces established process discipline rather than attempting to replace it. Without a production control framework, technology often becomes a repository of disconnected data rather than a driver of coordinated action.

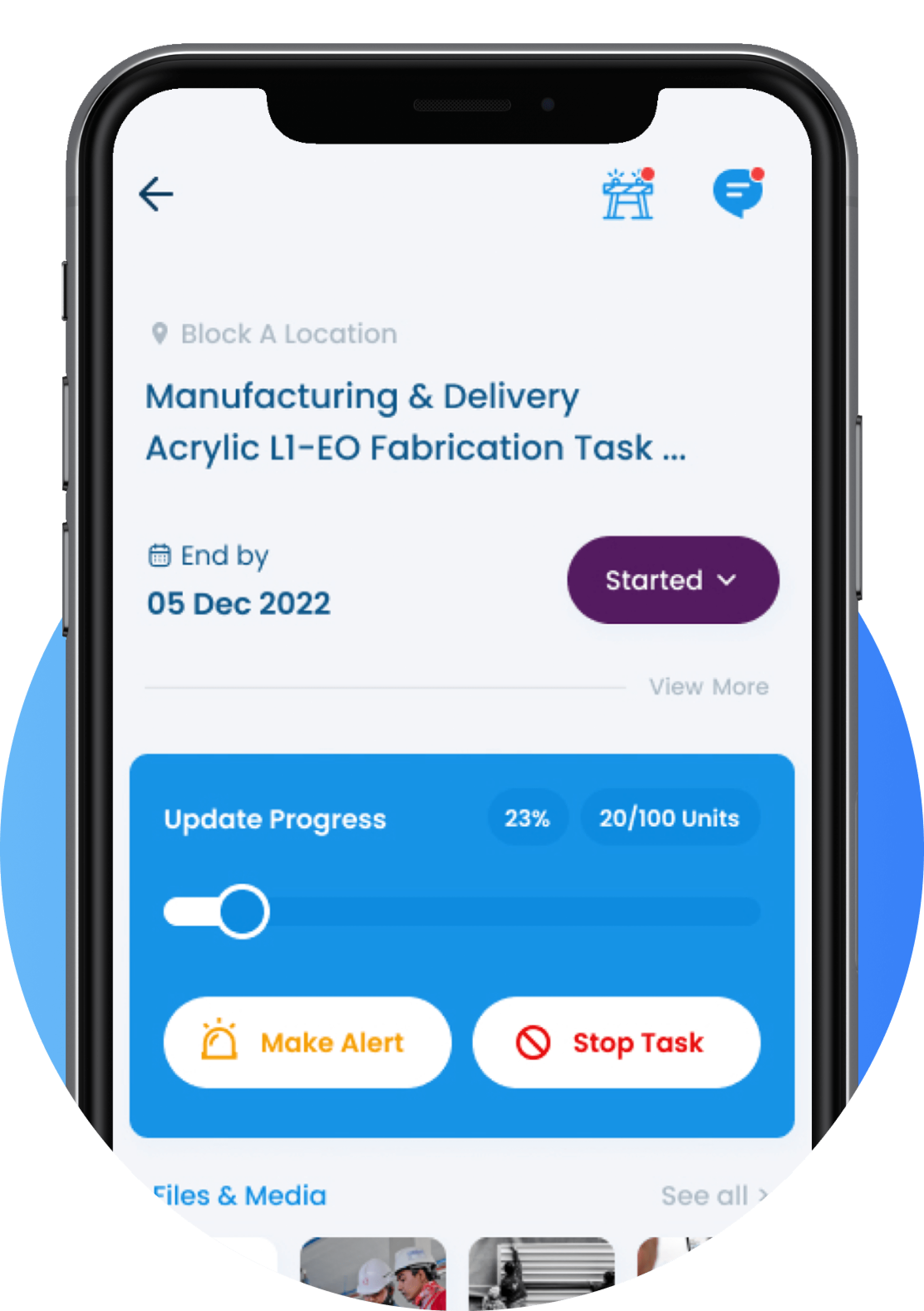

VisiLean addresses this by embedding the Collaborative Planning System into its operational workflows. This enables teams to collaboratively define work sequences, identify and remove constraints before they cause delays, and measure workflow reliability to support continuous improvement.

By directly linking ICT functions to Lean construction principles, VisiLean tackles the issue of production variability and ensures that planning translates into predictable execution — a challenge the paper identifies as a persistent gap in many construction projects.

Strengthening Communication and Trust

A core theme of the research is the application of Language Action Theory and promise-based management to improve project reliability. Construction projects fail not only because of process inefficiencies but also because of breakdowns in communication that erode trust among stakeholders. VisiLean operationalises this theoretical framework by creating a shared environment where commitments are explicitly recorded, progress is visible to all, and updates occur in real time. This reduces ambiguity, increases accountability, and transforms ICT from a passive reporting tool into an active mechanism for coordinating action and building reliability across the project supply chain.

Integrating BIM and 4D Modelling into Execution

The paper notes that BIM’s transformative potential is only realised when integrated with production control processes, yet in practice, BIM is too often confined to the design stage. VisiLean bridges this disconnect by linking model elements directly to live tasks and lookahead plans. This ensures that spatial and sequencing information from BIM and 4D models informs daily decision-making on-site. The result is improved requirements management, early identification of conflicts, and a visual representation of progress in its actual project context. This approach directly reflects the research’s call for ICT to act as a bridge between design intent and operational execution.

Ensuring Flexibility Through Adaptive Architecture

A recurring critique in the study is that conventional ICT systems lack flexibility, forcing projects to adapt to rigid software structures rather than the other way around. VisiLean’s cloud-based, mobile-enabled platform, grounded in Service-Oriented Architecture (SOA) principles, addresses this limitation. Its modular design allows project workflows, reporting tools, and data sources to be integrated or adapted as conditions evolve, avoiding the “islands of information” problem the research warns against. This adaptability ensures that the system remains responsive to project realities, whether in large-scale infrastructure builds or smaller, high-velocity projects.

Sustaining Improvements Across Projects

The research cautions that many ICT or Lean process initiatives succeed in limited pilot projects but fail to scale across an organisation. VisiLean mitigates this risk by combining Lean-based process management with an integrated digital environment that enables lessons learned on one project to be measured, standardised, and applied to future projects. This creates a continuous organisational learning cycle, where improvements are not only sustained but amplified over time. By institutionalising both the processes and the supporting technology, VisiLean delivers on the research’s vision of a truly integrated system that embeds performance gains into the fabric of an organisation’s project delivery approach.

Translating Research into Real-World Impact

The central message of the research is clear: lasting improvement in construction performance depends on deliberate integration of people, process, and ICT. Technology in isolation cannot overcome the deep-rooted fragmentation of the industry. Progress is achieved only when all three pillars operate in sync, reinforcing one another in daily project delivery.

VisiLean puts this principle into practice by providing a unified environment where Lean-based discipline, transparent communication, and adaptive digital tools converge. This alignment ensures that BIM models inform real-time execution, that commitments are tracked and honoured, and that performance improvements are measurable, repeatable and scalable.

For the construction industry, which is under constant pressure to deliver faster with fewer resources and better quality, the way forward is not isolated initiatives but a single, integrated system that embeds collaboration, discipline, and data-driven decision-making into every project. With such integration, construction can move beyond short-term gains towards sustainable and organisation-wide transformation.