We get asked this question more often than one would imagine. To answer this concern, we need to dive deep into what the Lean production management system claims and what it means to adopt Lean Construction or attain Lean maturity.

What is a Lean production management system?

Simply put, Lean is a way to define processes that can ensure smooth execution of activities on-site with minimum wastage of resources, while ensuring the needs of the supply chain are delivered at every stage. This requires a thorough review and ironing out of existing practices and workflows.

Concepts of Lean Production Theory

To further understand how the fundamentals of Lean correlate to planning and execution practices, it is necessary to get an overview of the key concepts of production theory.

Traditionally, the transformation view of production has been dominant, converting inputs to outputs. However, the flow view focuses on eliminating waste from processes, effectively ensuring that work and information flow uninterrupted.

A third view on production is value generation, with the basic goal of reaching the best possible value from the point of the “customer.” For the supply chain, every single handover acts as a customer.

Key ingredients of a good Lean production management system

The current industry requirement is not simply a production theory that fully integrates the transformation, flow, and value concepts, but also the right supporting tools to enable their adoption and implementation.

A sound Lean production management system incorporating these three concepts can enable the industry to transition towards Lean practices. Such a system would constitute the following aspects.

1. Address the core production processes

The system should target the core of construction management – the planning and execution of project activities on-site. Peripheral improvements are beneficial but secondary. The primary intent remains to ensure flow and value in production.

For example, Lean production management involves a close make-ready process to ensure the assignments are checked for prerequisites such as material, space, and manpower, before the work is actually started on-site. This considerably minimises unexpected halts or issues during the execution of the work, ensuring production flow and smooth handovers.

2. Integrate product and process on a single platform

With an overall view of generating value across the project delivery model for all stakeholders involved, the Lean model specifies the development of the product as well as process design in sync. This is in contrast to the traditional approach, where the product is first designed and then the contractors are generally called on board to come up with an execution strategy.

3. Support visual management principles

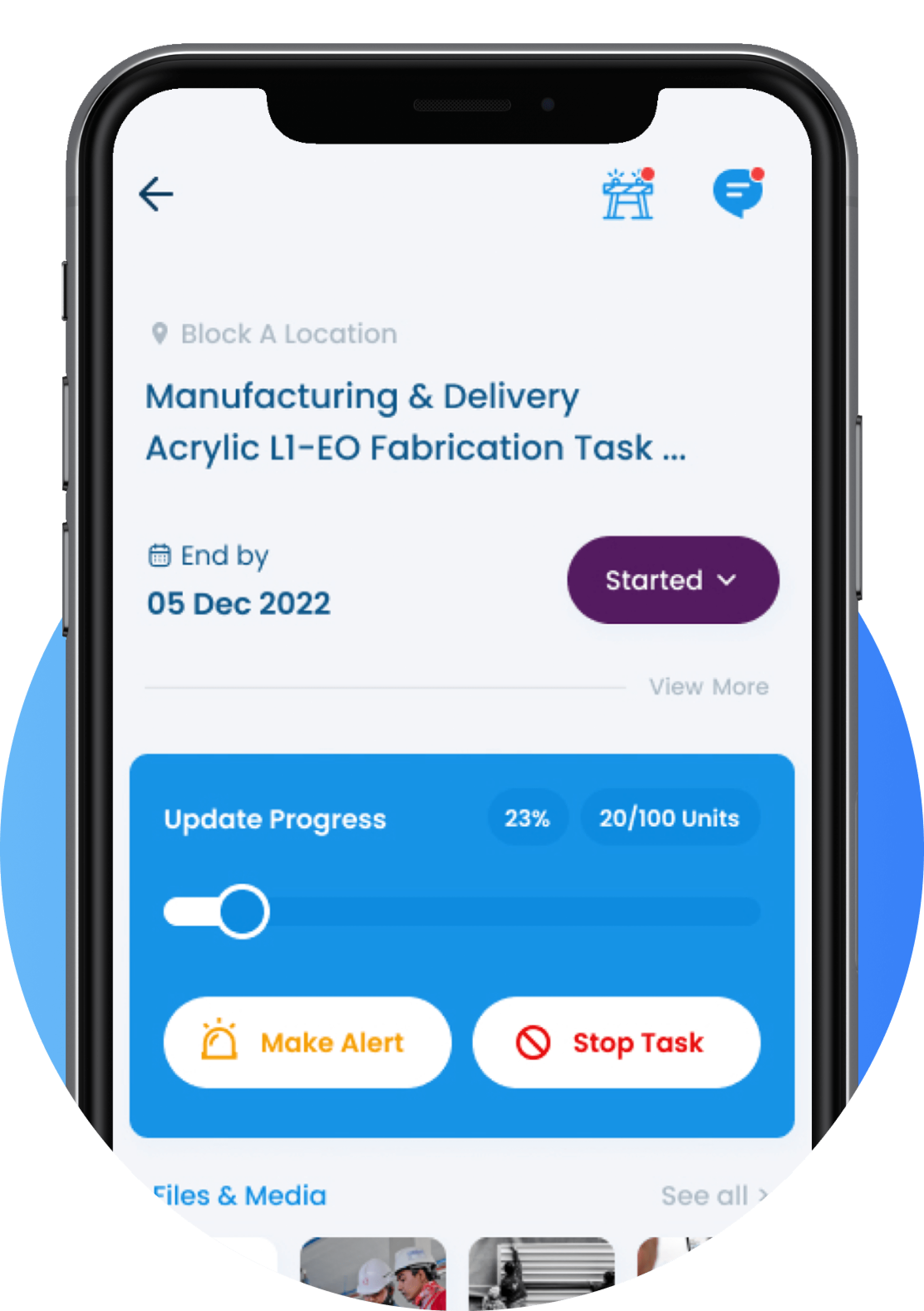

Lean philosophy describes visualisation as an excellent tool for offering a common language across teams. Visual management makes it simpler for people to discuss, integrate, and collaborate, thereby minimising waste in terms of information flow amongst project teams. Platforms supporting this make it easier for teams to collaborate towards efficient project delivery.

4. Address production flows with information flow

While traditionally decisions are simply “thrown over the wall” to the next person in line, the Lean model emphasises the involvement of the downstream for decision making. Rather than reactive approaches to push work in case of performance variances, a Lean production management model defines control by assessing the situation, establishing the root cause, coming up with solutions, and instilling an attitude of continuous improvement.

5. Do not lose sight of the larger picture

While focusing on addressing flow and bottom-up short-term planning, the team should not lose sight of the big picture, i.e. key milestones and deliverables. With the entire team aligned towards generating value for the end customer, the collaboration becomes much stronger in the case of a Lean model. This aligned interest allows for reliability in the entire chain of project delivery.

The “Lean” in VisiLean

While there are many differences between the Lean approach and current practice, a vital implementation milestone occurs when the project organisation shifts from only measuring the performance of each activity (the task view) to actively improving the predictable release of work from one specialist to the next (the flow view).

With VisiLean, we enable you to digitally provide this for your teams. There is no need to start with the theory; with VisiLean, your journey towards Lean maturity begins when your team starts to collaborate on the platform and activate it by providing real-time data from the site.

Start your Lean project management journey with VisiLean by signing up for a fully featured demo – https://visilean.com/demo-page/

To learn more about our Lean BIM features, head over to VisiLean Product Features