Building Information Modelling (BIM) strengthens this foundation by improving information flow and serving as a reliable reference point for planning, execution, and monitoring. Beyond 3D visualisation, BIM enables coordinated design reviews, clash detection, sequencing, and transparent communication across project teams. In doing so, BIM directly contributes to Lean outcomes such as reducing rework, enhancing workflow reliability and improving collaboration between stakeholders.

This synergy between Lean and BIM is widely recognised in both research and industry practice. While BIM is not the sole means of achieving the Lean outcomes, its ability to provide structured, accessible, and high-quality information significantly amplifies Lean’s effectiveness. The extent of this impact, however, is influenced by the maturity of BIM implementation—mature processes enable richer collaboration and more reliable decisions. In contrast, ad-hoc model development may still add value but with reduced impact.

This article examines BIM’s role as a Lean tool, focusing on how it drives better information flow, supports Lean principles, and the maturity challenges that shape its contribution to project delivery.

The Four Mechanisms Driving Lean-BIM Synergy

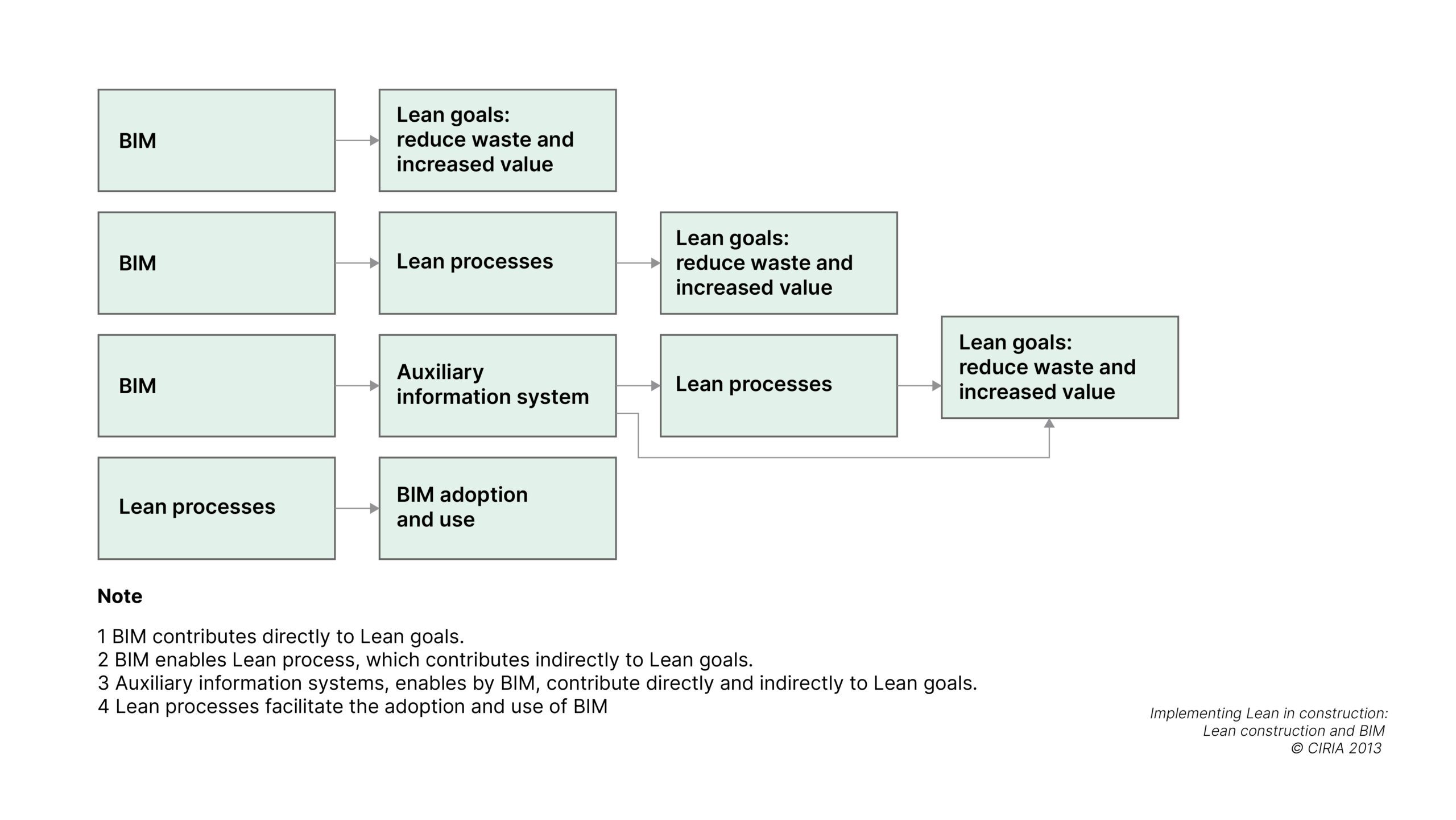

While Lean strengthens the production system or process to reduce waste and improve reliability, BIM acts as an enabler that amplifies these outcomes. Research and practice show that BIM strengthens Lean delivery through four key mechanisms:

i) Direct Waste Reduction

One of the most immediate benefits of BIM is its ability to cut waste at the source. Clash detection and coordinated 3D models, especially when used during production meetings, help project teams identify work conflicts long before they reach the site. This prevents costly rework, delays and unnecessary resource use – directly targeting Lean’s aim of eliminating waste. On projects where multiple trades overlap in tight spaces, such as hospitals or data centres, this mechanism alone can save weeks of corrective work.

ii) Enabling Lean Processes

BIM doesn’t just provide information – it creates the platform for Lean practices to thrive. Through 4D simulation, teams can virtually rehearse construction sequences, making planning sessions more reliable and collaborative. Trade contractors can see how their activities fit within the bigger picture, which supports smoother handovers and reduces uncertainty. In essence, BIM gives Lean’s collaborative planning tools the visual backbone they need to deliver predictable flow.

iii) Auxiliary Information Systems

Beyond clash detection and sequencing, BIM links seamlessly with other data-rich systems. Cost, energy, and carbon models can be integrated to inform Target Value Design (TVD) and set-based design approaches. This ensures decisions are not just about constructability, but also about optimising value for the client across the project lifecycle. By embedding these insights early, teams can balance cost, performance, and sustainability — a true reflection of Lean’s value-driven philosophy.

iv) Lean Processes Supporting BIM Adoption

Interestingly, the relationship works both ways. BIM may provide the tools, but Lean processes create the cultural environment for BIM to succeed. Regular Lookahead reviews, collaborative problem-solving, and continuous improvement cycles ensure that BIM data is actively used rather than sitting idle. Without Lean behaviours in place, BIM risks being reduced to a design tool. With Lean, it becomes part of a living, collaborative workflow that enhances daily decision-making.

What Projects Really Gain from BIM and Lean Integration?

The integration of BIM and Lean transforms how projects are delivered, creating benefits that extend far beyond the visual appeal of digital models. When both approaches are applied together, they address persistent challenges in construction such as variability, uncertainty, and fragmented workflows.

i) Reduced rework and design-related waste

BIM enables early identification of design conflicts through clash detection and coordinated reviews. In Lean terms, this eliminates defects and over-processing, which are among the biggest sources of waste. Projects that embed these practices consistently report lower volumes of Requests for Information (RFIs) and fewer change orders once construction begins.

ii) Improved workflow predictability

Through 4D simulations and virtual rehearsals (often called first-run studies), teams can test different construction sequences before they are executed on site. This proactive use of BIM supports Lean’s focus on reliable workflow and reduces the uncertainty that leads to waiting times and resource clashes.

iii) Shorter design and construction cycles

By synchronising models across disciplines and sharing them in joint review sessions, design iterations can be resolved faster. On the construction side, prefabrication and modularisation — both Lean-aligned strategies — are supported by BIM’s accurate digital data. The result is more streamlined cycles and reduced delays.

iv) Enhanced collaboration and communication

BIM acts as a “single source of truth” for project information. When combined with Lean routines such as Lookahead planning and collaborative planning meetings, the model becomes a shared reference point where decisions are made transparently. This fosters trust and reduces disputes between stakeholders.

v) Better data handover and lifecycle value

Mature BIM use ensures that the information captured during design and construction is structured for operations and maintenance. When aligned with Lean’s value-driven philosophy, this results in smoother handovers and facilities that are easier and more cost-effective to operate across their lifecycle.

The key insight depends on how intentionally BIM is woven into Lean processes. When BIM remains a stand-alone design tool, its benefits are limited. But when it becomes the information backbone of a Lean system, projects move from managing problems reactively to preventing them proactively — building with greater certainty, efficiency, and long-term value.

Challenges in Turning BIM into a Lean Tool

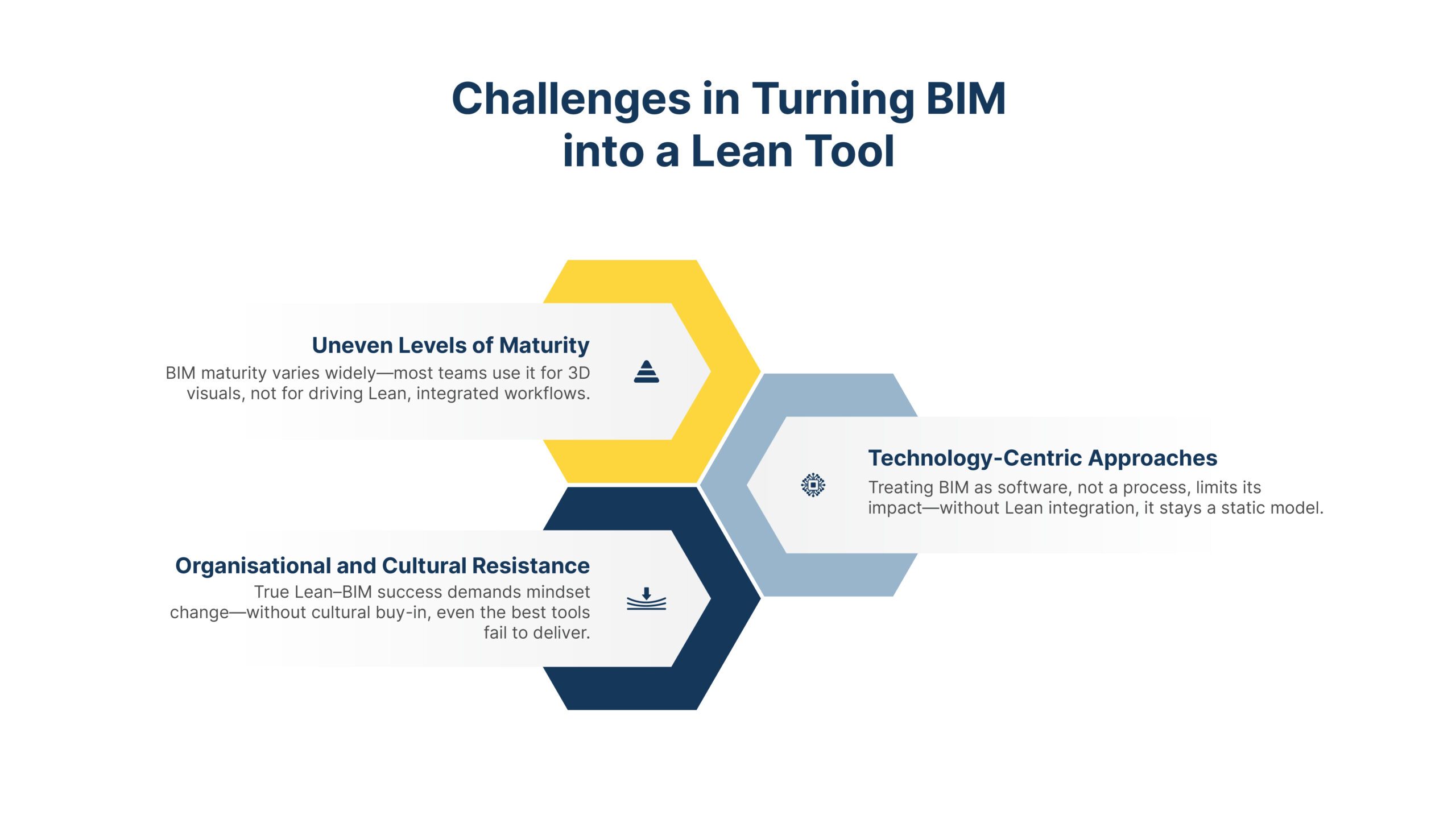

Despite the considerable potential of integrating BIM with Lean construction, its widespread adoption remains limited. The hesitation does not arise from uncertainty about its benefits — which are well documented — but rather from the practical barriers that organisations encounter when attempting to implement them. These challenges are multifaceted, encompassing issues of maturity, process alignment, contractual frameworks, and cultural readiness.

i) Uneven Levels of Maturity

The most significant barrier is the uneven maturity of BIM adoption across organisations, disciplines, and even individual projects. At a low level of maturity, BIM is typically restricted to 3D visualisation, which improves communication but contributes little to Lean objectives such as waste reduction or reliable workflow. At a medium level of maturity, more advanced functions such as clash detection, federated modelling, and 4D planning begin to reduce rework and improve predictability. However, benefits are often limited by fragmented processes and inconsistent uptake across project teams. Only at a high level of maturity, where BIM is integrated into production management, supports lifecycle modelling, and is embedded within Lean routines and collaborative contractual structures, can the full potential of Lean–BIM be realised.

ii) Technology-Centric Approaches

Another common challenge lies in treating BIM primarily as a technological solution rather than a process enabler. When BIM is viewed as software rather than as part of an integrated production system, it often remains a static representation of design intent. Without the support of Lean practices such as collaborative planning sessions, Lookahead reviews, and continuous improvement cycles, BIM fails to influence day-to-day decision-making on site. This disconnect results in limited impact on productivity and reinforces skepticism about its value.

iii) Organisational and Cultural Resistance

Finally, cultural factors remain a substantial obstacle. The successful application of Lean–BIM depends on behavioural change: increased transparency, shared ownership of planning, and the willingness to engage in iterative learning cycles. These behaviours require strong leadership commitment, training, and a departure from established ways of working. Without such support, teams may perceive Lean–BIM practices as disruptive or burdensome, particularly in fast-paced project environments where immediate delivery pressures dominate long-term process improvements. Resistance at this level undermines integration efforts and creates inconsistency across projects.

Enablers for Successful Lean–BIM Integration

Overcoming the barriers to Lean–BIM integration requires more than isolated technological upgrades. It demands a coordinated set of enablers that align people, processes, and contractual frameworks to support sustainable adoption. The following measures have emerged as critical for enabling BIM to function effectively as a Lean tool:

i) Building Maturity Through Structured Progression

Advancing from basic to high maturity is not an instantaneous shift but a staged process. Organisations should adopt a structured roadmap that prioritises incremental improvements: moving from 3D visualisation towards federated models, from ad-hoc coordination towards systematic clash detection, and ultimately towards model-driven production management. Regular maturity assessments help identify gaps and allow leadership to target investments where they generate the highest impact.

ii) Establishing Lean–BIM Champions

The presence of dedicated champions — both at organisational leadership and project delivery levels — is essential. These individuals act as translators between technical specialists and operational teams, ensuring that BIM outputs are systematically embedded in Lean workflows. Champions also play a pivotal role in overcoming cultural resistance by modelling collaborative behaviours and maintaining focus on continuous improvement.

iii) Aligning Contracts and Incentives

For Lean–BIM practices to thrive, contractual frameworks must support collaboration rather than competition. This requires moving away from lowest-cost tendering towards procurement strategies that incentivise joint problem-solving, data sharing, and long-term value creation. Models such as integrated project delivery (IPD) or partnering agreements create the alignment necessary for stakeholders to invest in Lean–BIM practices with confidence that benefits will be shared equitably.

iv) Creating Collaborative Environments

Physical or digital “big rooms” — shared spaces where multidisciplinary teams can engage with federated BIM models in real time — are powerful enablers of integration. These environments foster transparency, accelerate decision-making, and allow Lean routines such as Lookahead planning and first-run studies to be supported by model-based data. Establishing collaboration platforms of this kind ensures that BIM remains a living reference point throughout the project lifecycle.

v) Developing Skills and Embedding Routines

Finally, integration depends on the capability of teams to apply Lean–BIM practices consistently. Training must extend beyond software proficiency to include Lean principles, collaborative behaviours, and structured problem-solving methods. Embedding routines such as weekly Lookahead reviews, constraint analysis, and lessons-learned cycles ensures that BIM information flows are actively used to improve workflow reliability and eliminate waste.

Taken together, these enablers transform BIM from a digital artefact into a driver of Lean performance. By addressing the organisational, contractual, and cultural dimensions of integration, they create the conditions in which BIM can amplify Lean outcomes across the project lifecycle.

Conclusion: BIM as a Catalyst, not a Substitute

BIM and Lean are not competing approaches but mutually reinforcing elements of modern construction. Lean provides the principles and processes to minimise waste and maximise value, while BIM provides the information backbone to make those principles actionable. However, BIM alone cannot guarantee Lean outcomes. Its impact depends on the maturity of implementation, the contractual frameworks within which it operates, and the cultural readiness of project teams to embrace collaboration and continuous improvement. Where these factors align, BIM acts as a catalyst — turning Lean principles into measurable improvements in cost, time, and quality. For organisations seeking to advance project delivery, the priority should not be to “adopt BIM” in isolation but to embed it within a Lean framework. This is precisely where VisiLean delivers value. By uniting Lean planning workflows with BIM data in a single intuitive platform, VisiLean operationalises the synergy between people, process, and information. It enables teams to move beyond fragmented adoption and achieve the maturity required to unlock the full benefits of Lean–BIM integration.