The VisiLean Roundtable 2026 brought together industry leaders, researchers, and practitioners to examine a central question:

How does construction move beyond fragmented digital initiatives toward integrated control at project and portfolio scale?

Across the discussions, a consistent message emerged — technology alone is not the breakthrough. Real transformation lies in integrating production thinking, governance, and digital intelligence into a unified operating model.

Below are the defining insights from the session.

1. Dr Bhargav Dave: From Research Prototypes to Industry-Ready Production Systems

Dr Bhargav Dave opened the session by tracing the origins of Lean–digital integration in construction.

Early Integration of Lean and Digital Thinking

His early research, conducted alongside pioneers such as Rafael Sacks and Lauri Koskela, focused on bringing production principles and digital systems together — long before the industry was ready to adopt them.

Between 2004 and 2007, research prototypes were already embedding Lean logic into BIM-based workflows. What we now call “Digital Twin construction” is not a sudden breakthrough, but a natural evolution of those early experiments.

The Real Barrier Was Not Technology

One of the early challenges VisiLean faced was not product capability — it was industry readiness.

At the time, few organisations were willing to implement production management systems on live projects. Digital transformation was seen as experimental rather than operational.

Over time, however, the industry matured. Lessons from early implementations shaped a structured approach to rollout, onboarding, and change management.

Today, VisiLean supports firms with:

- Customised onboarding journeys

- Reality capture and drone-enabled workflows

- Integrated quality management

- Structured implementation services

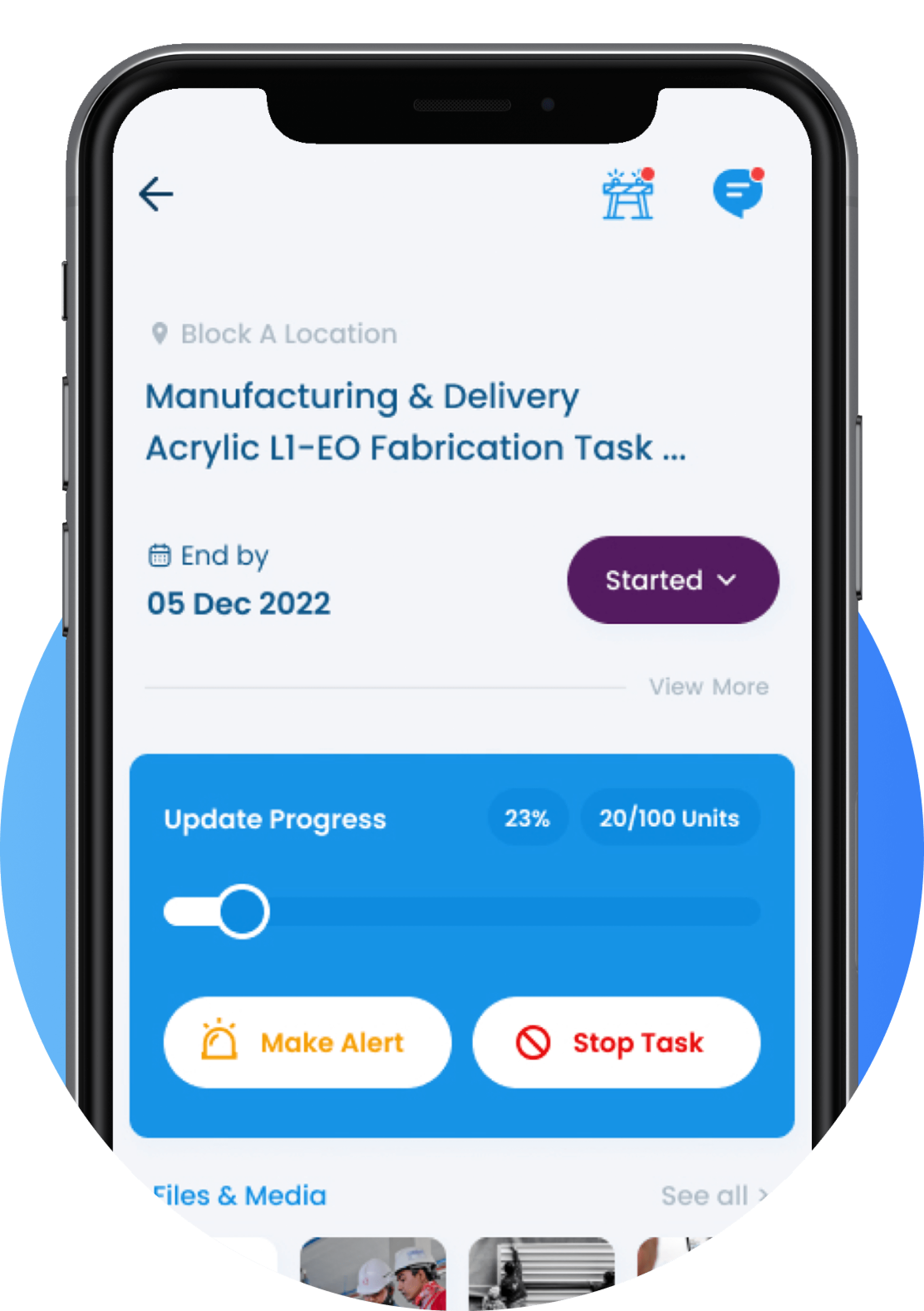

The platform itself has evolved from traditional architecture to a redesigned interface and now incorporates integrated modules across planning, execution, and quality.

An AI module is also being introduced — signalling the next phase of intelligent production management.

2. Prof Rafael Sacks: Digital Twins as Control Systems, Not Visual Models

Prof Rafael Sacks challenged one of the industry’s most common misconceptions: a Digital Twin is not a visual replica of a project — it is a control system. The distinction is critical.

BIM represents design intent.

A Digital Shadow enables monitoring by reflecting what is happening on site.

A true Digital Twin goes beyond simply existing; it closes the loop by integrating real-time monitoring with feedback mechanisms that inform decisions and actively influence outcomes.

In other words, a Digital Twin must do more than display status. It must shape action.

The Three Foundations of Digital Twin Construction

Prof Rafael Sacks framed Digital Twin construction not as a standalone technology, but as the outcome of four interdependent foundations:

- Building Information Modelling (BIM)

- Lean construction

- AI-enabled intelligence

- BIM–Lean synergy leading to Digital Twin construction.

He explained that each plays a distinct role.

BIM structures design intent. It provides the digital backbone of the project — geometry, systems, quantities, and relationships. But on its own, BIM remains a representation of what should be built.

Lean construction introduces production logic. It focuses on flow, sequencing, stability, and the systematic removal of constraints. It defines how work should move across locations and over time.

AI-enabled intelligence strengthens this foundation by helping teams interpret patterns, identify risks earlier, and move from reporting what has happened to anticipating what might happen next.

What truly enables Digital Twin construction, however, is the synergy between BIM and Lean. When structured design data is directly connected to production planning and continuously updated with field realities, the model begins to reflect not just the building, but the state of production itself.

In that moment, the system shifts from documentation to control.

Flow and Waste Are the Same Objective

One of the most powerful insights came from Lean theory.

Traditionally, Lean emphasises two goals:

- Smooth flow

- Waste reduction

But Prof Sacks explained they are fundamentally the same.

If production flows continuously, waste disappears naturally.

Construction, however, differs from manufacturing. Work does not move — crews move through locations over time. Floors, zones, and rooms behave like products in a line-of-balance system. Crews should move steadily like trains on tracks, avoiding stacking and waiting.

From Project Optimisation to Portfolio Intelligence

Another strategic shift discussed was scale.

Subcontractors and suppliers operate across multiple projects simultaneously. Optimising one project in isolation is insufficient.

The real opportunity lies in portfolio-level coordination, enabled by digital systems that synchronise labour, materials, and schedules across projects.

The Intelligence Ladder

Prof Sacks outlined a progression:

Data → Information → Knowledge → Prediction → Optimisation

Competitive advantage does not sit in data collection.

It sits in prediction and optimisation.

He described the Digital Twin lifecycle as a continuous loop:

Design → Plan → Build → Monitor → Interpret → Learn → Predict → Control

Most companies stop at monitoring.

The real value begins at control.

3. Rahul Sharma: Digital Maturity and the Move Beyond Pilots

Rahul Sharma presented a stark reality: construction remains one of the least digitised industries.

More than 70% of organisations remain in early digital maturity stages (Digital Explorer or Digital Player). Fewer than 4% reach Digital Transformer or Digital Disruptor levels.

Common issues include:

- Project-specific digital pilots

- Disconnected tools

- Minimal R&D investment (often below 1% of revenue)

- Poor linkage between technology and finance

At TATA, the approach has been different.

Technology is embedded in mission, vision, and governance.

The focus is not just cost progress, but fiscal progress.

A critical industry gap in India today is on-site decision-making speed. Data exists, but decisions lag.

Unless technology is linked directly to governance and finance, transformation remains superficial.

The message was clear:

The industry must move beyond pilots. Adoption at scale is the real challenge.

4. Pallav Saxena: Role-Based Visibility and Decision-Centric Dashboards

Pallav Saxena emphasised that speed directly affects asset monetisation.

At Smartworld, digital transformation is anchored on four principles:

- Customer centricity

- Professionalism

- Digital transformation

- Continuous innovation

Managing 12 active projects worth approximately ₹11,000 crore, the organisation has recognised that dashboards alone do not drive performance.

He quoted a powerful line:

Not everything that counts can be counted, and not everything that can be counted counts.

Digital platforms must surface what truly matters for each role:

- Leadership needs a strategic overview

- Project managers need execution insights

- PMOs need site visibility

- Site teams need transparency into PMO actions

Without role-based clarity, visibility creates noise rather than control.

Integrated, role-based systems are essential for faster decision-making across complex portfolios.

5. Sachin Bansal: Governance at Scale

Sachin Bansal discussed governance across geographically distributed infrastructure portfolios.

Their transformation focused on:

Standardise → Visualise → Give leadership direct access → Reduce review time → Improve decisions

Key outcomes included:

- Standardised reporting frameworks across projects

- Critical path-focused reviews

- Leadership and independent director system access

- Reduced management meeting time

- Faster review cycles

The biggest gain was not better reporting — it was faster governance and proactive control.

The shift was from reactive firefighting to structured oversight.

6. Kalyan Vaidyanathan: Change Management Is the Hardest Problem

Kalyan Vaidyanathan closed the session with a fundamentals-first perspective.

The biggest barrier to digital transformation is not software.

It is behavioural resistance.

Construction is inherently fragmented, making integration difficult. Legacy ecosystems create inertia.

He described adoption as a hockey-stick curve:

Slow at first → Rapid acceleration after tipping point.

Sustainable transformation requires:

Simple, practical tools (bottom-up adoption)

Strong leadership direction (top-down governance)

The model is clear:

Simple tools + Leadership mandate = Sustainable change

Incremental improvement will not be enough to meet India’s growth scale. Structural change is required.

Conclusion: From Experimentation to Integrated Control

The VisiLean Roundtable 2026 underscored a defining shift in construction: the conversation is no longer about adopting digital tools, but about integrating them into the core of production and governance. Lean thinking, BIM, Digital Twins, and AI each play a distinct role, yet their real value emerges only when they operate as a connected system. Fragmented initiatives and isolated pilots cannot deliver structural change. What the industry requires is an operating model where information flows seamlessly from design to planning, execution, monitoring, and control.

Construction’s complexity makes this integration both challenging and essential. Projects are location-based, resource-shared, and shaped by multiple stakeholders working across portfolios. In such an environment, productivity cannot be improved through reporting alone. It improves when decision-making becomes faster, clearer, and rooted in real-time insight. Moving from monitoring to prediction, and from prediction to proactive control, marks the transition from reactive management to disciplined governance at scale.