If your projects keep hitting targets on paper but still end up costing more than expected, you’re not alone. Across the world, construction companies are watching their profits slip, even as their teams work harder than ever.

Margins in this industry are notoriously tight, hovering around 2% to 10%, and the pressure to deliver faster keeps growing. Yet here’s the reality: most of the margin loss doesn’t come from dramatic failures. It comes from the small, daily inefficiencies that go unnoticed until handover. A missed update, a late approval, a design issue caught too late, they all stack up quietly.

And there’s one common thread behind it all: a lack of connected, digital ways of working. McKinsey’s 2024 report found that construction productivity has grown by barely 1% per year in two decades, while digital-first industries have doubled that rate. In simple terms, we’re still managing modern projects with traditional tools and it’s costing us real money.

Digitalisation is about giving your team real-time visibility, predictable workflows, and fewer surprises. Because in today’s construction environment, every uncertainty has a price tag and every minute without data clarity eats into your margins.

Where Do You Lose Money During Construction?

Money doesn’t vanish from a project in one big moment; it leaks out slowly. A tiny delay here, a missed update there, a design issue spotted a bit too late. These everyday slip-ups quietly chip away at your margin. And the tricky part? You usually realise it only when the project is already running over time or budget.

Rework

Rework occurs when work must be redone because the original execution was flawed, incomplete or misaligned.

It’s a significant silent cost: industry research indicates that rework typically represents about 4% to 6% of the total project cost in the reported cases. Other studies show that the range can span from 2% up to 20% of the contract value, depending on project type and the measurement method used.

In a detailed breakdown, it’s noted that up to 70% of rework is design-induced and about 25% of rework is caused by poor project data or miscommunication. The implication for tight margin projects is profound: even a 5% rework cost can wipe out the expected margin and add schedule risk.

Delays in approvals and decision making

When approval workflows, sign-offs, or decisions by a client, consultant, or regulator are slow, the project encounters idle labour, equipment downtime, extended overheads and disrupted site sequencing – all of which cost money.

While specific global quantifications for just the approval-delay piece are more fragmented, one study noted that 77.8% of infrastructure projects in India reported delays, and of these, 58% had 10-30% time overrun, 25% had 31-50%, and 19% had 51-100%.

Another study cataloguing delays causes identifies delayed decisions and slow approval of design documents consistently among the top factors. In short, decision- and approval-related waiting is a frequent and expensive problem that is often invisible in standard project dashboards.

Poor Communication Between Teams

When teams (field, design, procurement, project control) are not aligned or don’t share accurate, timely data, the result is misunderstandings, duplicated work, execution errors, and rework.

The Project Management Institute estimates that in the U.S., miscommunication and poor project data cost about $31.3 billion annually in construction through rework and delays.

Another finding: projects with low communication effectiveness had only 48% delivered within budget, compared with 76% for highly effective communication.

So, the impact isn’t just a large absolute cost, it undermines schedule and budget performance across the board.

Inefficient Resource Allocation

Resources (labour, equipment and materials) must be matched to tasks, sequenced correctly and responsive to change. When they are not, cost creeps in, idle equipment, inefficient overtime labour, mis‑sequenced trades, or material waits all amplify cost.

While quantification is less precise in public data for this one, industry commentary links poor resource allocation with up to 23% of project failures and significant losses from overtime and idle time.

The lesson: even if your line‑items (labour, material, plant) look within budget, the hidden cost of mis‑allocation can erode margin quietly.

Late Detection of Issues

Problems caught late (design clashes, scope changes, site constraints, permit issues) cascade into larger cost overruns.

One analysis found that about 70% of construction projects experience schedule delays, and 64% go over budget, often due to late detection of issues.

This means that by the time a design conflict is discovered mid‑construction, not only are costs higher, but the schedule is disrupted as well. The chain reaction is expensive in terms of labour, productivity and management time.

How VisiLean can Save You Money?

Most cost overruns don’t come from big mistakes. They happen because planning and execution on-site don’t match. Plans change, updates are missed and before you know it, time and money slip away.

That’s where VisiLean steps in. Built on Lean Construction principles, VisiLean brings your planning, BIM, and live site execution together in one connected space. Here’s how we save you money;

Eliminate Rework

Rework is one of the biggest profit killers. Even a small design mistake or outdated drawing can mean days of extra labour and material waste.

Through VisiLean, your teams always work on the latest plan. Any change to the design or schedule is reflected instantly across the system.

If there’s a clash or a constraint, it gets flagged before the work starts — not after the concrete is poured.

With live updates and BIM integration, VisiLean helps cut that loss down dramatically.

Fast-track Approvals

We’ve all been there: the site team’s waiting on a sign-off, the next trades are on standby, and the clock keeps ticking.

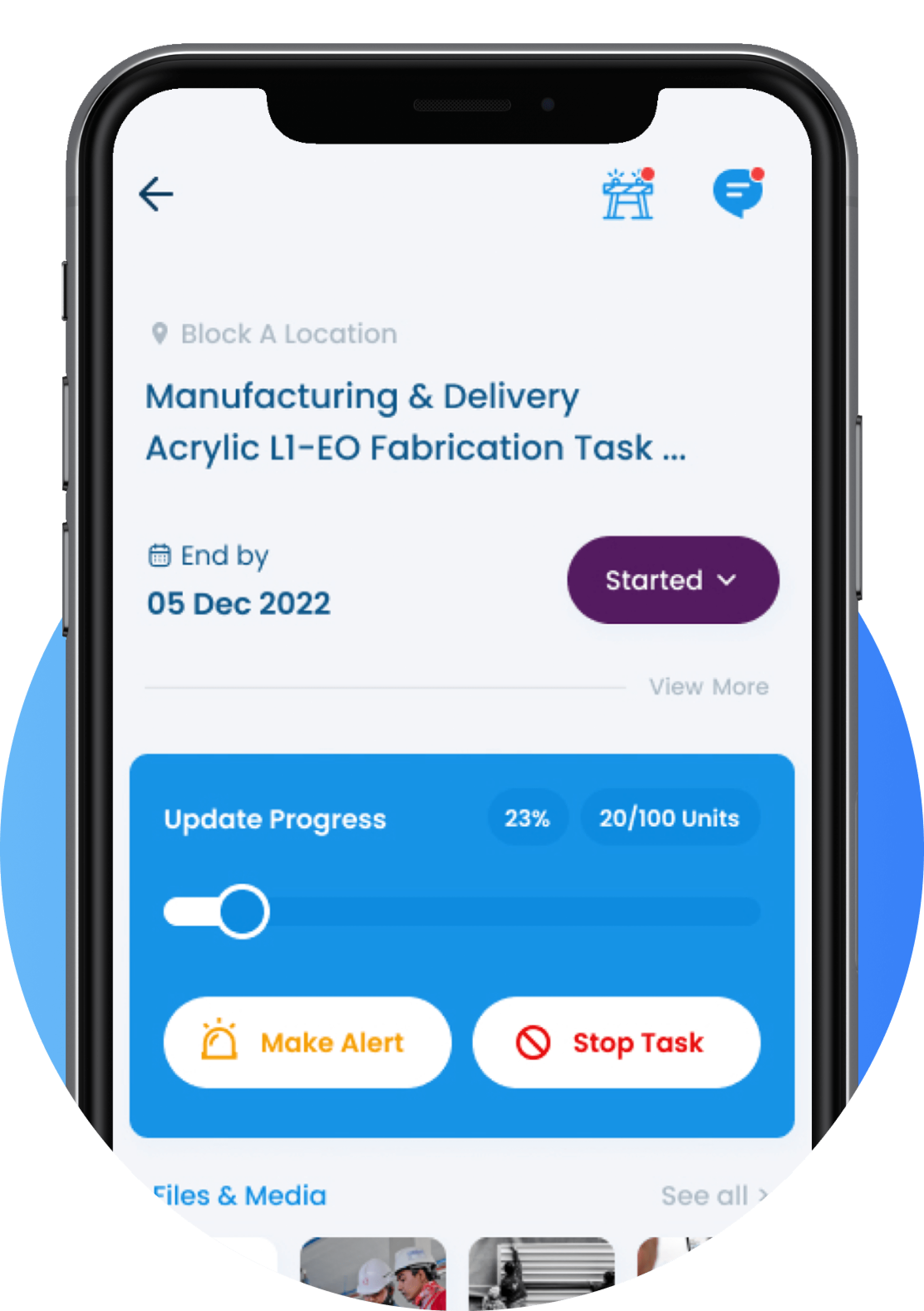

VisiLean takes the waiting out of the process. With mobile checklists, digital sign-offs, and instant notifications, approvals and RFIs move faster. Managers don’t need to dig through emails; they can approve directly from their phone.

That means fewer idle hours, smoother handovers, and no more waiting for those signature moments.

Everyone on the Same Page

Miscommunication is expensive. In fact, poor communication costs the construction industry over $30 billion in rework and delays each year.

VisiLean connects everyone, from the office and the site to subcontractors and clients, on one live platform. You can monitor who is doing what, what has been completed and what is delayed, all in real time.

No more chasing updates or working off different spreadsheets. Just clear, up-to-date information that keeps your team aligned and your project moving.

Make the Most of Your Resources

Idle machines, mismatched crews, and last-minute overtime, they all chip away at your profits. With VisiLean’s live task tracking and integrated schedule, you can plan resources smarter.

The system shows where you’re overstaffed, where you’re short, and what’s coming up next. That way, your labour, equipment, and materials are always where they’re needed most.

It’s not just about cutting costs; it’s about getting more done with what you already have.

Catch Issues Before They Cost You

By the time a design clash or scope change shows up on site, fixing it can blow your budget.

VisiLean helps you catch those problems early. With constraint management and visual dashboards, you can see potential blockers before they hit the schedule. Whether it’s a late material delivery or a design conflict, you’ll know about it before it causes a delay.

That means fewer surprises, more predictability, and a plan that actually stays on track.

If You Remember One Thing, Let It Be This!

The truth is, margin loss in construction rarely comes from one significant error; it comes from hundreds of small disconnects that pile up over the life of a project. Rework, slow approvals, unclear communication, and issues spotted too late are all symptoms of the same underlying problem: teams are working hard, but not always with the right information at the right time.

As projects get more complex and timelines get tighter, relying on disconnected tools or manual updates simply isn’t enough. The industry’s long-standing productivity challenge isn’t because people aren’t capable; it’s because the systems around them haven’t kept up with the pace of modern delivery.

Digitalisation isn’t just a trend; it’s becoming the foundation of predictable, profitable construction. When you’re planning and site execution finally come together in a single, connected workflow, the daily chaos quiets down. Decisions move faster. Mistakes are caught earlier. Teams stay aligned. And the hidden costs that quietly erode your margins begin to disappear.

That’s precisely what VisiLean brings to your projects; not just another set of dashboards, but a platform that connects plans, models, and real-time site updates in one place. The real value is the clarity and confidence it gives you: knowing that what you planned is what gets built, on time, on budget, and without the constant firefighting.

Book a demo to know more.