Construction execution is where most plans are tested and often fail to meet expectations. Despite having detailed master schedules and 4D models, teams on the ground struggle to keep up with the pace due to operational inefficiencies. The root of the issue is the lack of a production management system that integrates both process and product data into a single connected environment. This is where Lean (process) and Building Information Modelling (product) integrated workflows become crucial.

Lean construction management provides a structured approach to planning and executing work, focusing on flow and continuous improvement. BIM, on the other hand, offers clarity on the product being built, with model-based insights into scope, sequencing and coordination. But while each system has proven value, most tools today treat them in isolation, overlooking the potential of a truly synchronised environment.

VisiLean simplifies this by offering a production management system that supports Lean construction workflows and BIM. Let’s walk you through how this takes shape on your projects through our dynamic and centralised platform.

Table of Contents

- How Does BIM Support Lean Construction?

- Aligning Process and Product for Coordinated Execution

- Supporting Pull Planning and Task Readiness

- Using BIM to Plan for Safety and Constructability

- Supporting Constraint Checks Through Visual Task Context

- Enabling Data-Driven Decision Making

- Bringing Production to Life, Not Just the Plan

- FAQs

How Does BIM Support Lean Construction?

Lean construction management and BIM address two different but equally critical challenges in project execution—workflow reliability and spatial clarity. When used together, they offer a powerful synergy that improves coordination, task readiness, and overall delivery performance. This section explores how this combined approach transforms day-to-day construction management into a more predictable, collaborative, and model-driven process.

Aligning Process and Product for Coordinated Execution

A fundamental goal of Lean construction is to create a reliable workflow by ensuring that only tasks with all prerequisites in place are released for execution, referred to as the Make-ready process. For this to work reliably, teams need more than a schedule; they need clarity on where that work will take place, what physical components it involves, and how it fits into the larger spatial and sequencing context of the project. This is where BIM becomes critical when integrated with Lean planning. BIM enables a direct link between tasks and their corresponding model elements. By adopting VisiLean as a production management system that supports BIM and Lean, construction activities are no longer treated as abstract line items but instead are tied to specific components, locations, and zones. This connection enhances the accuracy of lookahead plans, facilitates early detection of clashes, and ensures that teams understand precisely what they are committing to during planning sessions.

Supporting Pull Planning and Task Readiness

Pull planning involves planning in reverse from a defined milestone or phase completion. Rather than pushing activities forward based on assumed durations, teams collaboratively identify the final activity required to achieve a target and work backwards to determine all preceding tasks. This reverse sequencing enables teams to construct a reliable and optimised workflow that fits within the available timeframe while maintaining alignment with project goals.

This approach fosters collaboration among stakeholders, allowing them to negotiate task durations, dependencies and handoffs in a way that ensures sequence is both realistic and collectively owned. This outcome is a more resilient plan that minimises waste, prevents overlooked steps, and improves workflow reliability.

When integrated with Building Information Modelling (BIM), the effectiveness of pull planning is significantly enhanced. BIM introduces visual clarity and spatial understanding into the planning process, enabling teams to assess the scope and sequence of work in direct relation to the physical model.

Using BIM to Plan for Safety and Constructability

BIM visualisation plays a crucial role in improving on-site planning by making constructability and safety risks visible before execution begins. With access to the model, teams can assess whether scaffolding blocks access paths, if multiple trades are scheduled in the same area, or if temporary structures may create conflicts—all of which can be addressed proactively during planning.

Safety planning also becomes more precise. High-risk tasks can be identified early and appropriately flagged in the model. This allows teams to plan safety measures in advance and helps adjacent trades coordinate their work to avoid exposure to hazards.

By integrating these visual insights into daily planning routines, VisiLean ensures that constructability reviews and safety checks are not isolated activities—they become a core part of how teams prepare for work. The result is a more coordinated, predictable, and safer construction environment.

Supporting Constraint Checks Through Visual Task Context

In traditional systems, constraint management is often handled through fragmented notes, multiple meetings, or standalone spreadsheets that lack visibility. When Lean construction is practised without integrated digital support, identifying and resolving these constraints becomes a reactive rather than a proactive process. A production management system that supports both Lean methodology and BIM can fundamentally change how constraints are surfaced and addressed. VisiLean enables this visual representation of tasks within the BIM environment, enabling planners and field engineers to identify conflicts early. During lookahead planning or weekly coordination meetings, these model-linked insights help teams make faster, more informed decisions that directly support the reliability of their short-term work plans. Constraint resolution becomes a shared responsibility, not an isolated task, thus reinforcing the Lean principle of making work ready before it is released to the site.

Enabling Data-Driven Decision Making

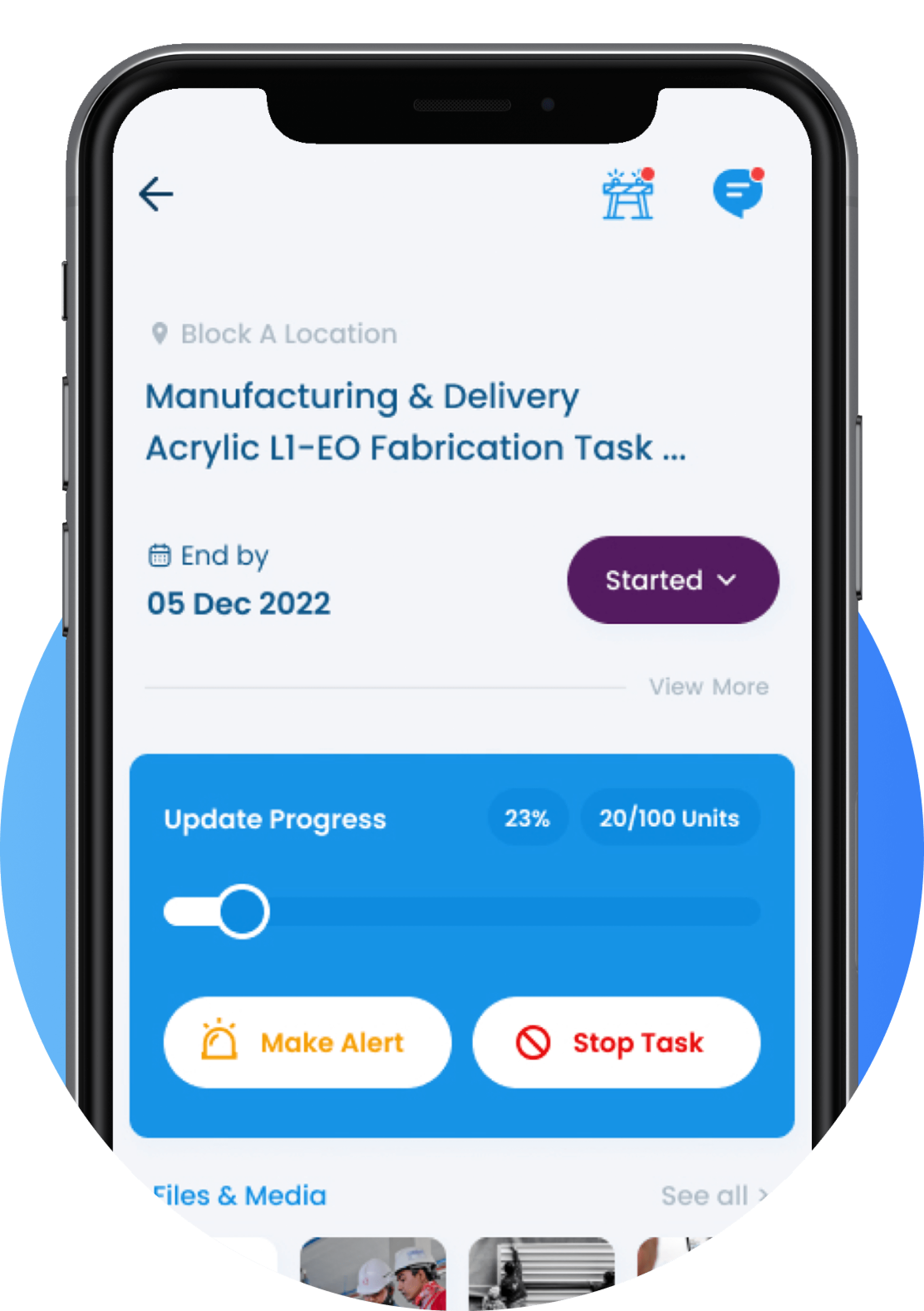

A connected production management system, such as VisiLean, introduces a disciplined, data-centric approach to improvement. By aligning model-based tracking with Lean performance metrics, our platform generates a continuous feedback loop between planning, execution, and learning. Each completed task with missed commitment and resolved constraint is documented not just as an outcome, but as part of a broader pattern that can be analysed for root causes.

Crucially, when integrated with BIM, this process gains an additional dimension. BIM has the ability to serve as a long-term carrier of project data, capturing how tasks were executed, what challenges were encountered, and how they were resolved. Over time, this accumulated intelligence supports not just individual project optimisation, but cross-project learning at an organisational level. Furthermore, this structured visibility supports Lean practices such as the lookahead meetings, offering a reliable foundation for team-level learning and organisational process improvement. Over time, these patterns help construction teams not only avoid repeating mistakes but also build a culture of predictability, accountability, and continuous value delivery.

Bringing Production to Life, Not Just the Plan

Construction projects often fail to meet expectations because plans and execution are not well aligned. Lean and BIM offer solutions but using them separately still leaves gaps on-site. Through VisiLean, these gaps are closed. Tasks are linked to model elements; constraints are visible before they become problems, and teams work with real context. Every update from the field reflects directly in the plan. Every decision is backed by visual and reliable data.

If your current system separates planning from the model or relies on disconnected updates, it’s not built for how construction really works. VisiLean brings Lean and BIM together—so your production system does more than scheduled work. It supports it visually, collaboratively, and in real time.

Don’t delay, book a demo today and let’s discuss how VisiLean can transform your construction projects.

FAQs

What is a production management system in construction?

A production management system in construction is a platform or method used to plan, monitor, and control project execution. It ensures that tasks are delivered on time, resources are optimised, and workflows remain efficient, especially important for large or complex construction projects.

How does Lean construction support the production management system?

Lean construction enhances production management by focusing on workflow reliability, reducing waste, and improving planning. It uses methods like pull planning and constraint management to ensure that only ready tasks are executed, leading to better predictability and efficiency.

What is the role of BIM in production management?

Building Information Modelling (BIM) supports production management by offering 4D visualisation of construction elements, helping teams understand the scope, sequence, and spatial context of tasks. This clarity helps in better coordination, fewer clashes, and real-time alignment of planning with execution.

How does VisiLean improve lookahead planning and task readiness?

With BIM-integrated planning, VisiLean is the best construction scheduling software that enables teams to verify task readiness based on real-world model data. During lookahead sessions, teams can visually check constraints, dependencies, and sequencing, ensuring that upcoming tasks are feasible before being committed to.

What are the benefits of model-linked task planning?

Model-linked tasks help teams visualise what is being built, where, and when. This reduces miscommunication, enhances field coordination, and makes it easier to detect clashes or missing inputs early, supporting better short-term planning and long-term project control.