There is no denying the fact that we lead busy lives. Overflowing to-do lists, unanswered emails, stress, and lifestyle diseases – this is life as we know it now. Kind gestures and compassion are increasingly becoming a rarity. However, there are little acts that can make a whole lot of difference in this world every day. T. S. Eliot refers to three Sanskrit words, namely ‘Datta. Dayadhvam. Damyata’ in his classic work “The Waste Land”. These words loosely translate to ‘give, be compassionate and be in control.’ And these words put into action, we believe will make all the difference and this is our core strength. Here is a look at how we, at VisiLean, have impacted the lives around us.

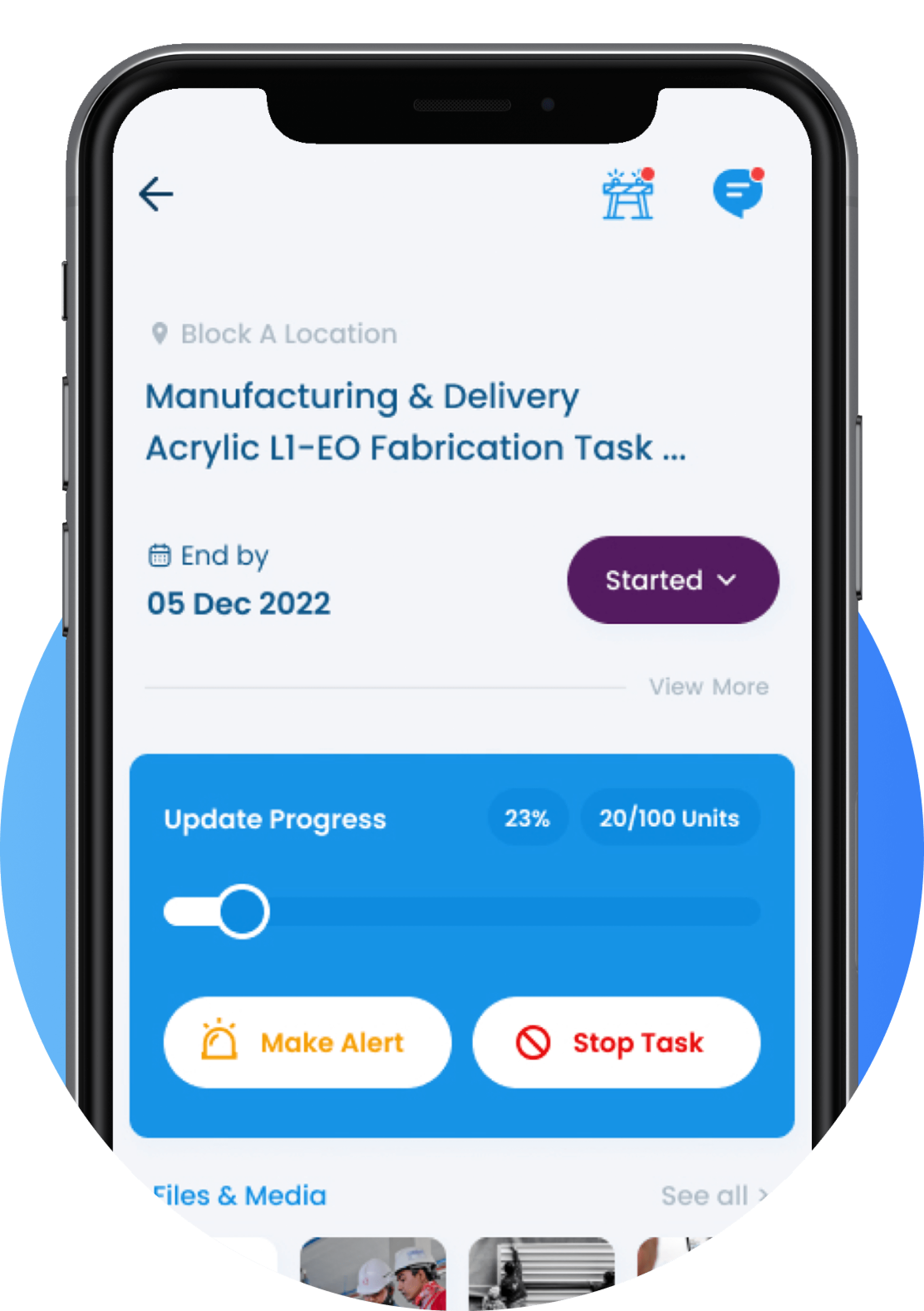

At VisiLean, we are proud to share that we touch lives – every single day. We try to transform lives with the support of technology. Across projects, VisiLean has allowed teams to remove a lot of the old-school manual ways and enhance productivity by adding technology. Even through the global pandemic, VisiLean played a critical role in ensuring safety on jobsites by enabling planning through a safe-distancing approach. The best part, undoubtedly, has to be the fact that some clients have been successful in reducing their working hours due to increased efficiency. This has allowed most of our clients to spend more quality time with their families, and lead better lives; Isn’t that amazing?

VisiLean has been fortunate to extend its services not just as a software provider, but also as experts in the domains of Lean Construction and Production Management. Over the years we have conducted webinars, workshops, and seminars on the various aspects of Lean Construction. For our Solution Specialist Vijayashree TM, it was exciting to host an online workshop on “Decoding Lean in Production Management through Digitalisation” for the students at Nihon University specializing in Lean and Digitisation in Industrial Engineering. The workshop focused on challenges in the supply chain and conventional planning and introduced the students to the concepts of Lean thinking for production management through a lean-BIM integrated solution approach.

The story of how we have touched the life of an M.Sc student at Nihon University is an inspiring one. VisiLean has collaborated with Nihon University for exploring the system design that supports ‘Designed for Manufacturing and Assembly (DfMA)’ in construction. The research journey started with Professor Koichi Murata, bringing in his production wisdom and their fellow M.Sc. student, Mucahit Tetik who has devoted his time and efforts to practically conducting the research. VisiLean R&D team including Viranj Patel, Vikas Patel, and Dhruvi Whadhwana, along with Mucahit conducted a case study based exploration followed by numerous engagement and brainstorming sessions discussing the alignment of completely different industries and their operations, through digital and Lean workflows.

Through this brief endeavour, the exploration team has gathered key ingredients and considerations that constitute the development of a DfMA-supported construction management system. The team has explored a novel method addressing the need for production tools in construction. The research team is now devising a blueprint to navigate the uncharted territory where the variability of the construction world integrates seamlessly with the highly controlled production environment. This research will make a sea of difference in the days to come.

We supported Maika Maposa, a student at the University of Huddersfield for his dissertation – Evaluation of Software systems for the Last Planner® System (LPS). The research explores the efficiency of software systems supporting LPS. The research motivation was to evaluate software systems used to enhance production planning to produce predictable workflows.

And that is not all. We have always been keen on giving back to our Alma Mater in whatever ways we can. Our CEO and co-founder Dr. Bhargav Dave has been teaching at CEPT University since his return to India in 2016. As part of the Faculty of technology, M.Tech. Course of Construction Engineering and Management, he teaches Integrated Construction Practices covering Lean and BIM implementation as part of the 3rd Semester Studio every year along with Co-tutor Dr. Jyoti Trivedi. The studio is designed to enable students to deploy process improvement collaborative practices driven by Lean tools and principles through various digital agencies centered around BIM as the single source of truth.

The students are directly exposed to the industry for the implementation of these exercises to gain real-world insights into the challenges and opportunities offered by industry professionals. The results of this interaction have been very fruitful with numerous students taking their careers forward in the direction of digital construction methods for delivering projects more effectively and efficiently. Within VisiLean itself, we have managed to recruit our team of Solutions Specialists like Paramjit Lota and Vijayashree TM from CEPT University. And for Paramjit, who is now himself a co-tutor of the ICP studio course with Dr. Bhargav Dave, it is all about taking the legacy forward.

The team has been extensively involved in delivering guest lectures, exposing students to our clients across the globe as well as new tools and processes that are being adopted as part of best practices in the industry. We have also had the opportunity to take members of the ILCC 2020 Conference through a detailed workshop on “Decoding the ‘lean’ in production management”.

Are you interested in being associated with us? Don’t get left behind. Discover how VisiLean can touch lives, and enable your teams to be more efficient. Want to know more? Head to our YouTube channel , or visit our website, to learn about all our features and book a demo with our team!